How to optimize your encoder system

When striving to enhance the performance and reliability of ...

How many ways are there to improve the design, quality, accuracy, performance and process reliability of your robots?

Our new e-book will show you 12 ways using HEIDENHAIN rotary encoders!

The new level of CNC control: TNC7

HEIDENHAIN presents the TNC7. It can be operated intuitively and supports the entire manufacturing process.

Cutting edge careers

As a leader in motion control, positioned at the forefront of technological research development, the HEIDENHAIN team is an exciting one to be a part of.

TNC Club: Meeting point for experts

At the TNC Club, CNC experts can find support and solutions to all questions relating to TNC controls from HEIDENHAIN.

More videos, articles, news

Get the latest product announcements, trend breakdowns and technical insight directly from our engineers in our blog.

HEIDENHAIN develops and manufactures linear encoders, angle encoders, rotary encoders, digital readouts, and CNC controls for demanding positioning tasks.

Are you searching for a specific encoder? Use our new encoder selector tool to find the right one for your needs.

HEIDENHAIN is at home in numerous industries. Discover solutions from the HEIDENHAIN Corporate Group for your application. Discuss your requirements with our sales engineers, and let our brands support your market success with their extensive product portfolios and strong industry expertise.

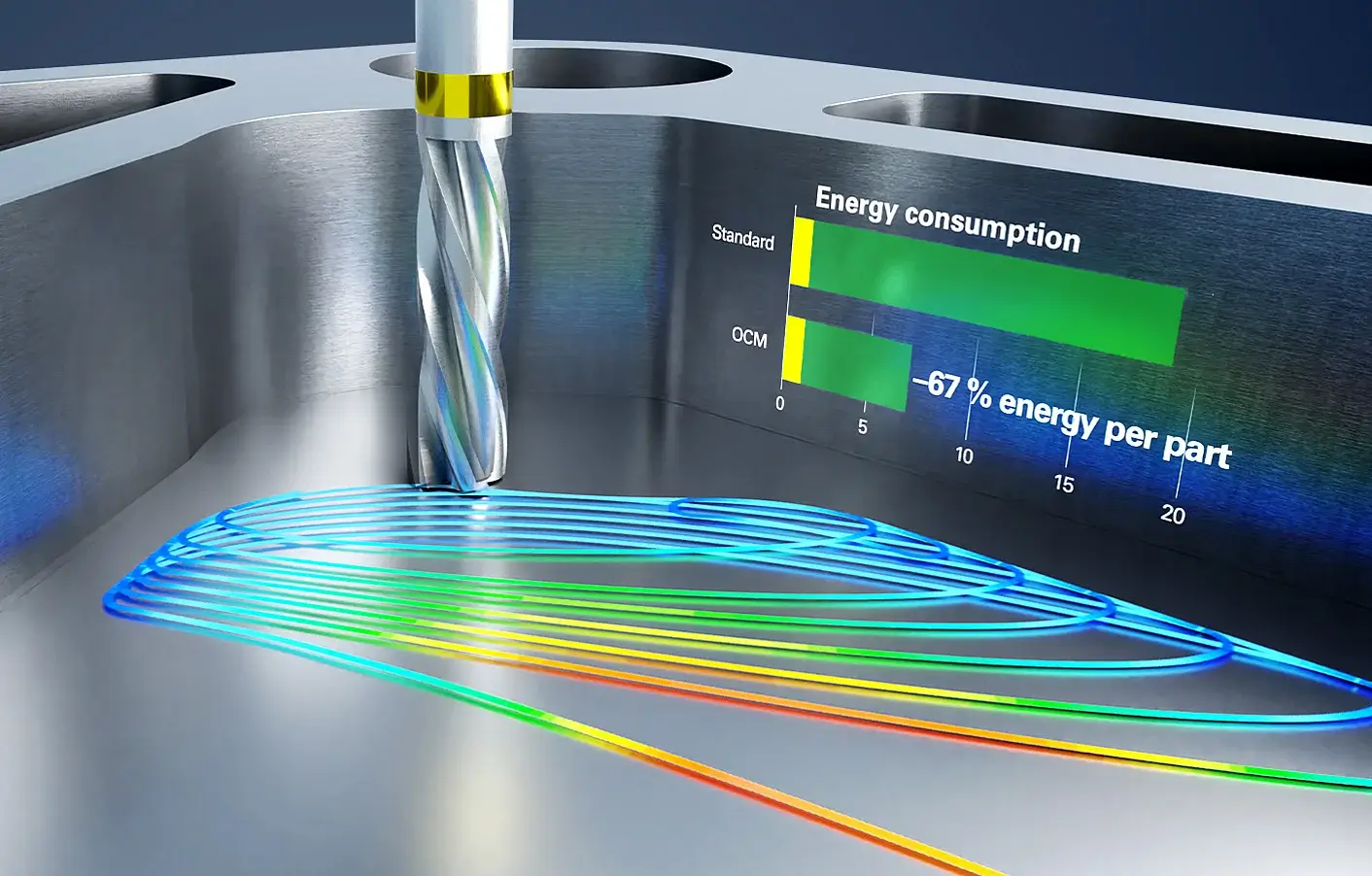

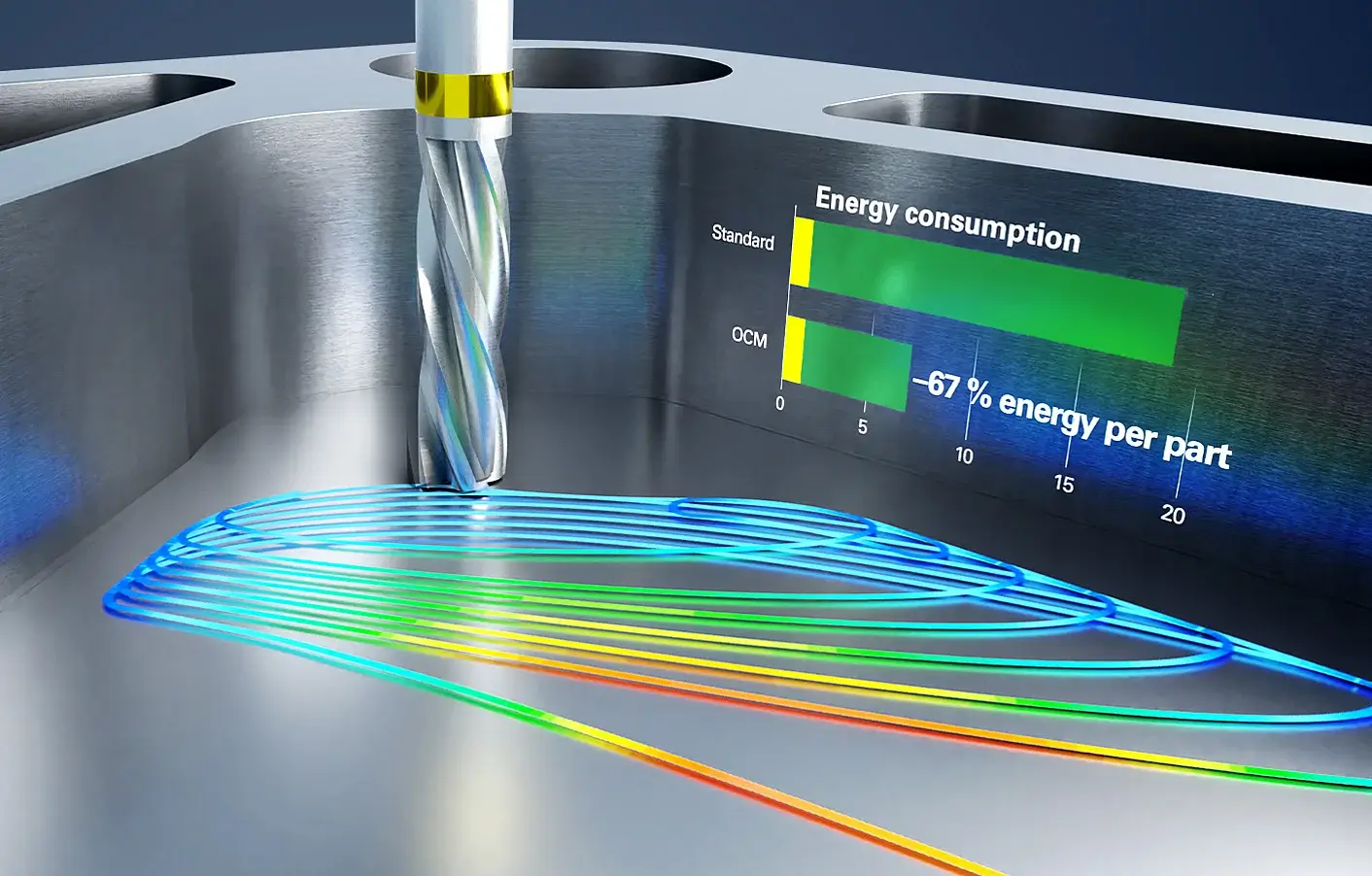

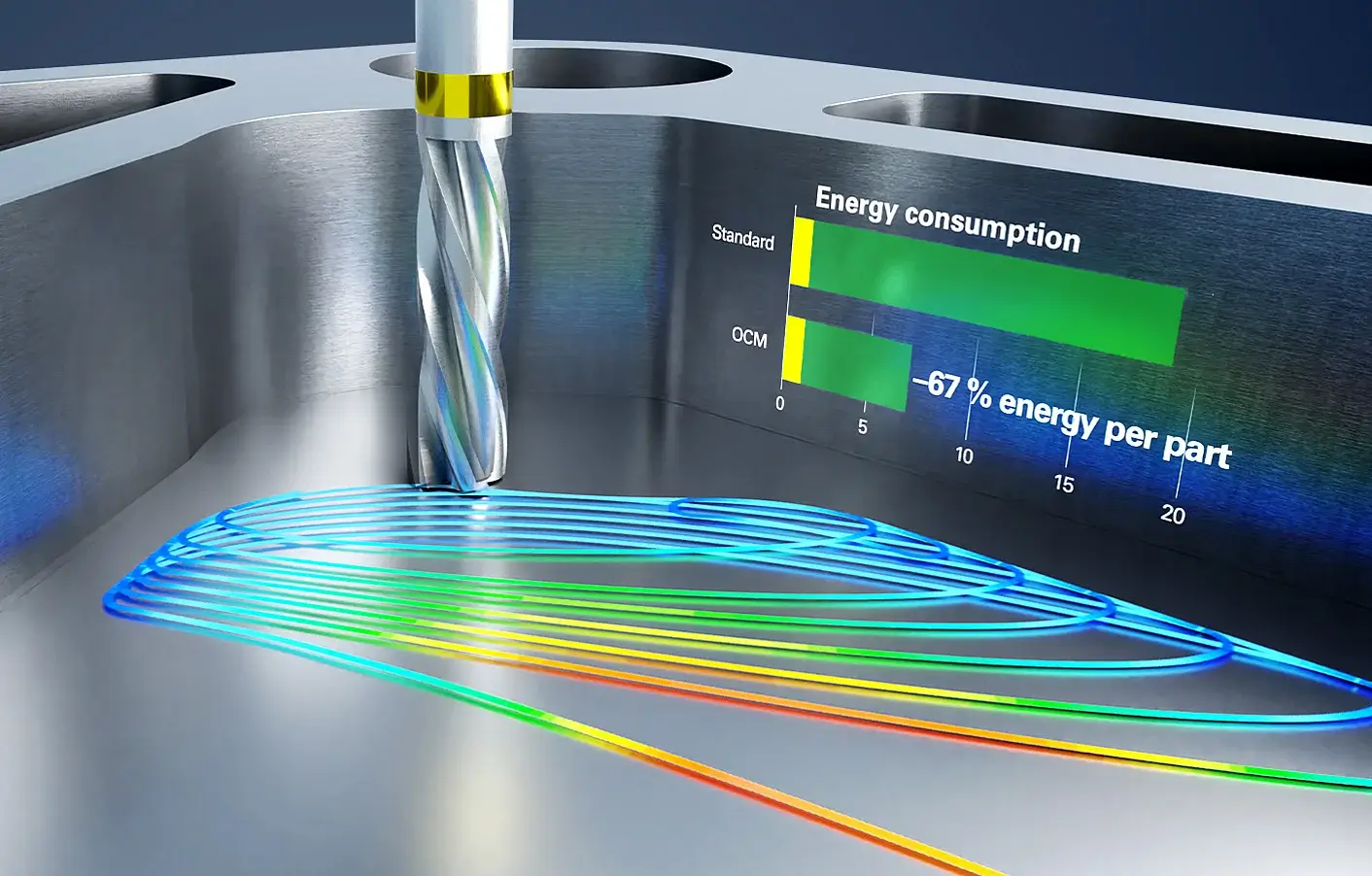

Optimized Contour Milling (OCM) uses next-generation trochoidal milling to achieve up to 67% time and energy savings during roughing, finishing and smart deburring while maximizing process reliability. Users merely define the contour and apply the optimal machining parameters from a built-in cutting data calculator. The TNC control then automatically determines the best trochoidal milling strategy for any desired pockets and islands.

Chiplet technology and new mid-end-of-line processes in semiconductor manufacturing have laid the groundwork for artificial intelligence, humanoid robots and self-driving vehicles. Advances in production miniaturization have downscaled the distance between electrical contacts to 2 microns, thus reaching a key milestone. But even smaller structures are attainable at greater throughput with the HEIDENHAIN encoders and ETEL motion systems being showcased at SEMICON West 2024.

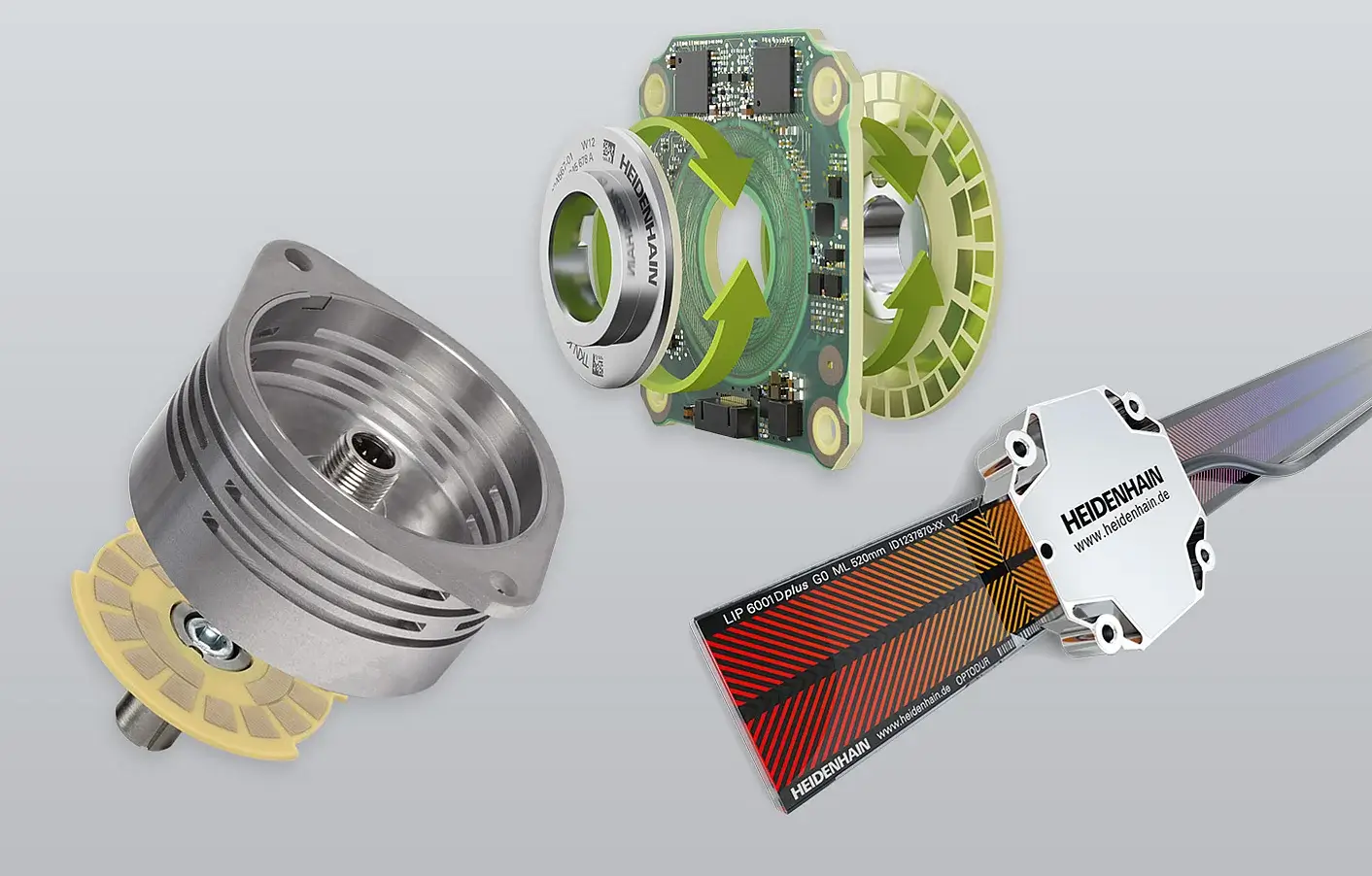

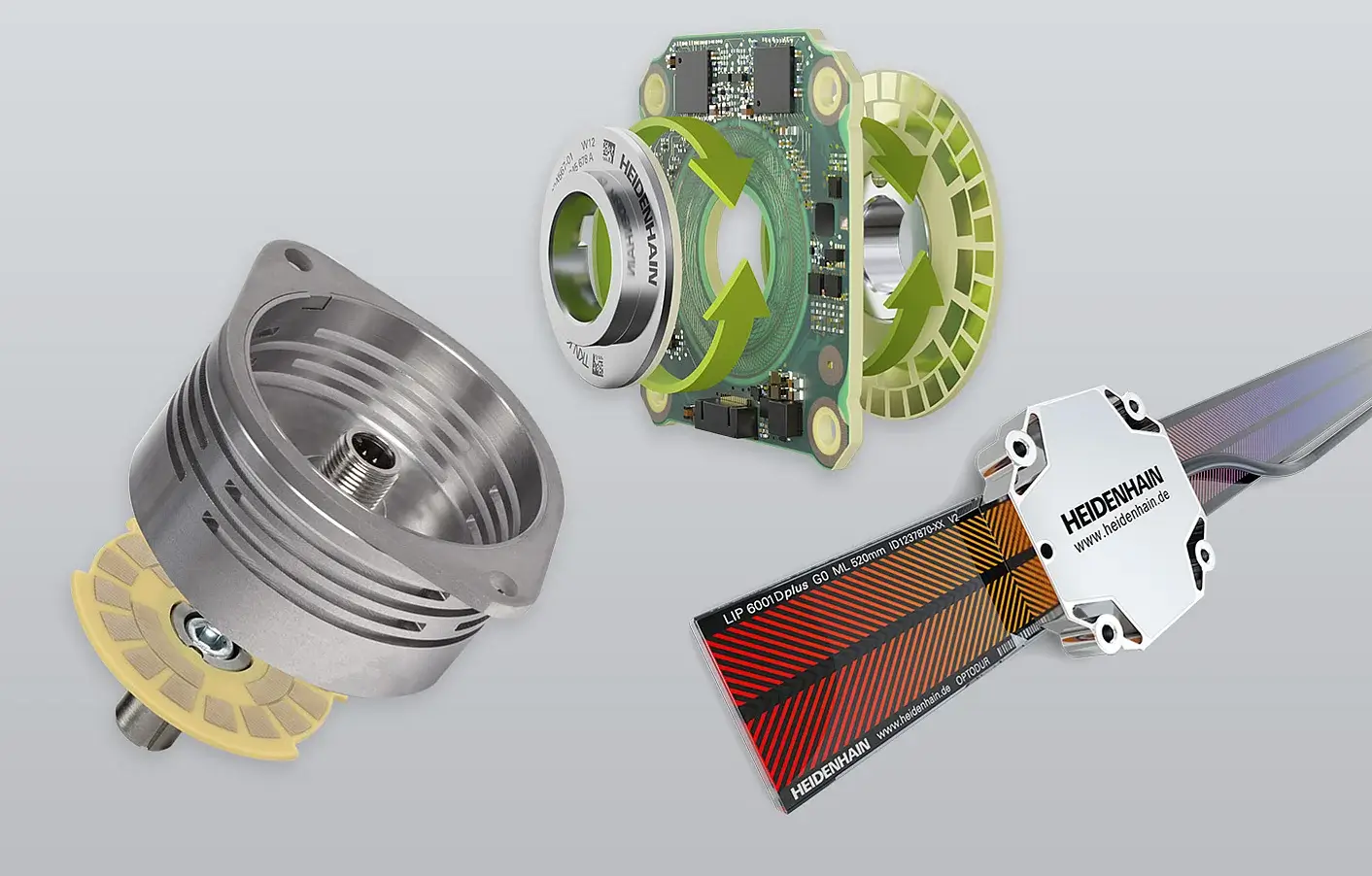

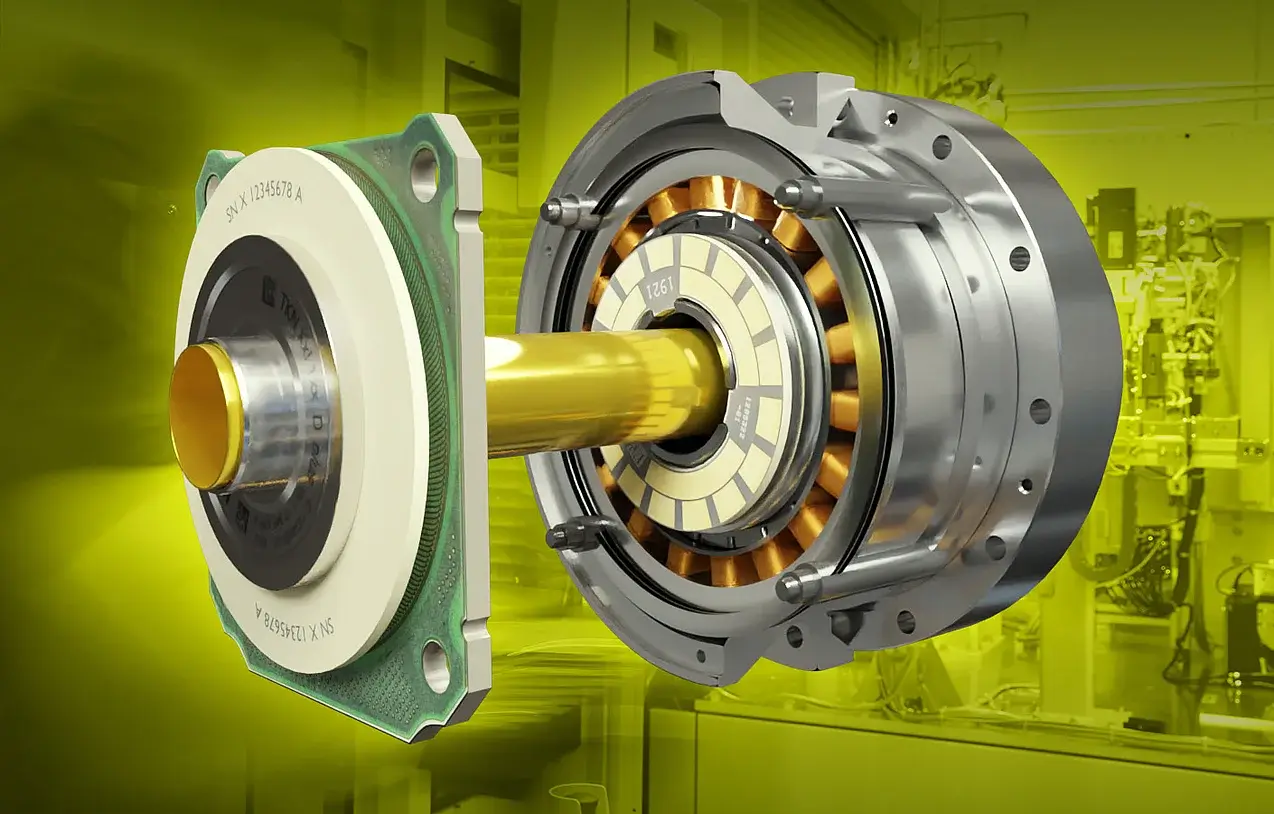

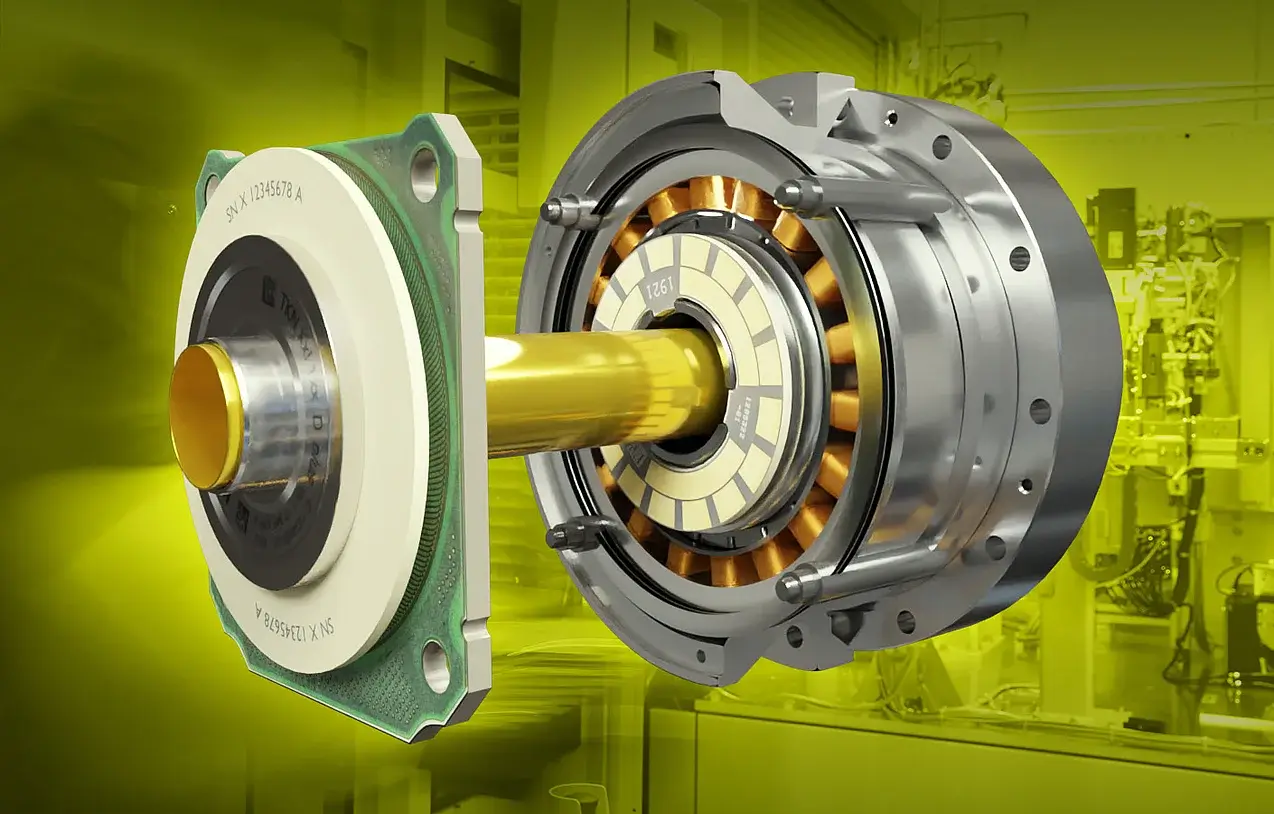

Our Dplus encoders share a remarkable capability: multi-dimensional motion feedback. In robotics, the inductive KCI 120 Dplus provides rotary position feedback both upstream and downstream from a robot joint’s gearing, thus raising TCP accuracy and simplifying cobot design. On elevator motors, the KCI 419 Dplus merges angular position feedback with continuous brake-stroke monitoring for greater operational reliability. And for chipmaking challenges, such as finer structures in hybrid bonding, the LIP 6000 Dplus drives up system accuracy by tracking secondary motion orthogonal to its primary linear axis.

Optimized Contour Milling (OCM) uses next-generation trochoidal milling to achieve up to 67% time and energy savings during roughing, finishing and smart deburring while maximizing process reliability. Users merely define the contour and apply the optimal machining parameters from a built-in cutting data calculator. The TNC control then automatically determines the best trochoidal milling strategy for any desired pockets and islands.

Chiplet technology and new mid-end-of-line processes in semiconductor manufacturing have laid the groundwork for artificial intelligence, humanoid robots and self-driving vehicles. Advances in production miniaturization have downscaled the distance between electrical contacts to 2 microns, thus reaching a key milestone. But even smaller structures are attainable at greater throughput with the HEIDENHAIN encoders and ETEL motion systems being showcased at SEMICON West 2024.

Our Dplus encoders share a remarkable capability: multi-dimensional motion feedback. In robotics, the inductive KCI 120 Dplus provides rotary position feedback both upstream and downstream from a robot joint’s gearing, thus raising TCP accuracy and simplifying cobot design. On elevator motors, the KCI 419 Dplus merges angular position feedback with continuous brake-stroke monitoring for greater operational reliability. And for chipmaking challenges, such as finer structures in hybrid bonding, the LIP 6000 Dplus drives up system accuracy by tracking secondary motion orthogonal to its primary linear axis.

Optimized Contour Milling (OCM) uses next-generation trochoidal milling to achieve up to 67% time and energy savings during roughing, finishing and smart deburring while maximizing process reliability. Users merely define the contour and apply the optimal machining parameters from a built-in cutting data calculator. The TNC control then automatically determines the best trochoidal milling strategy for any desired pockets and islands.

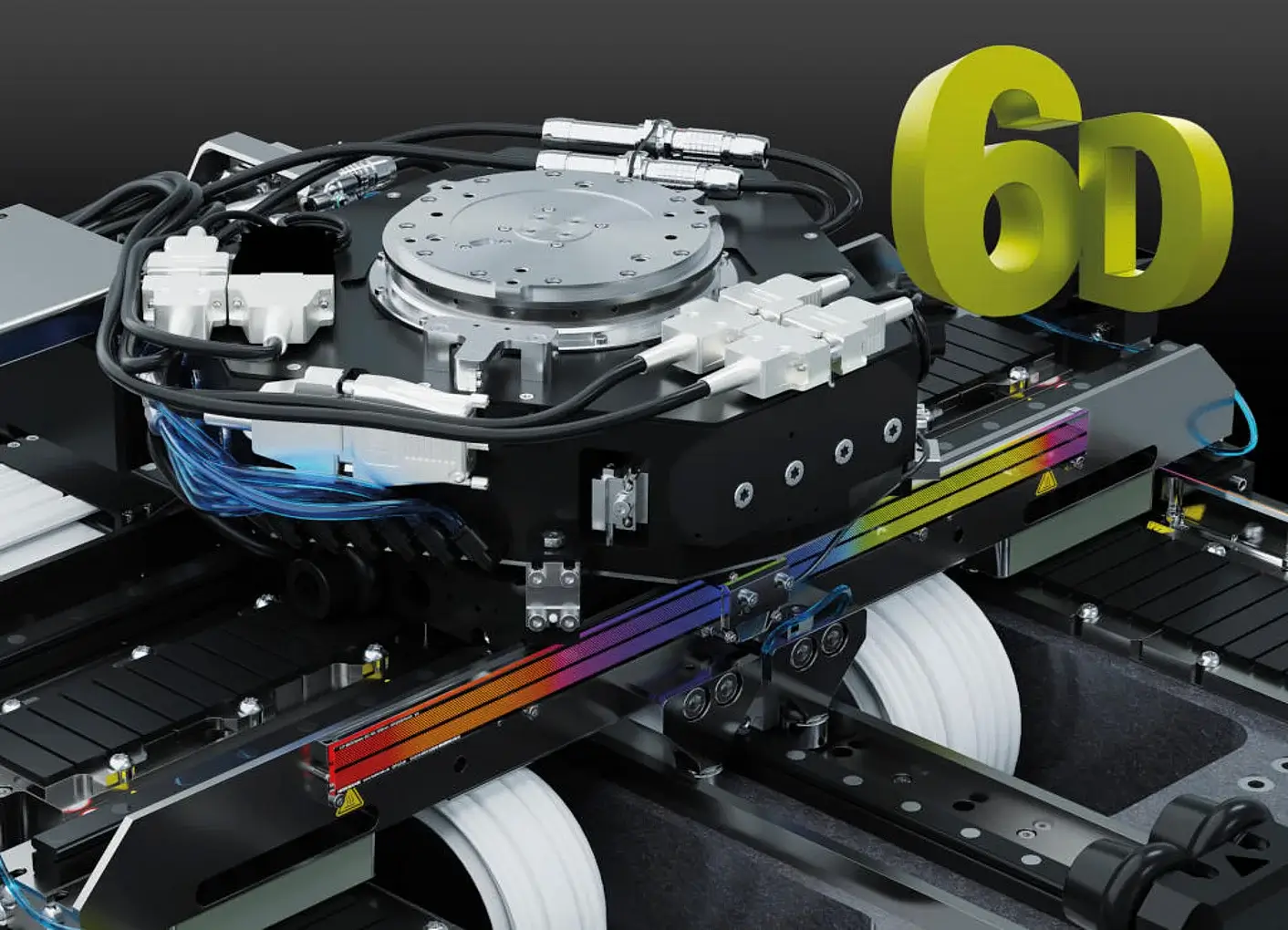

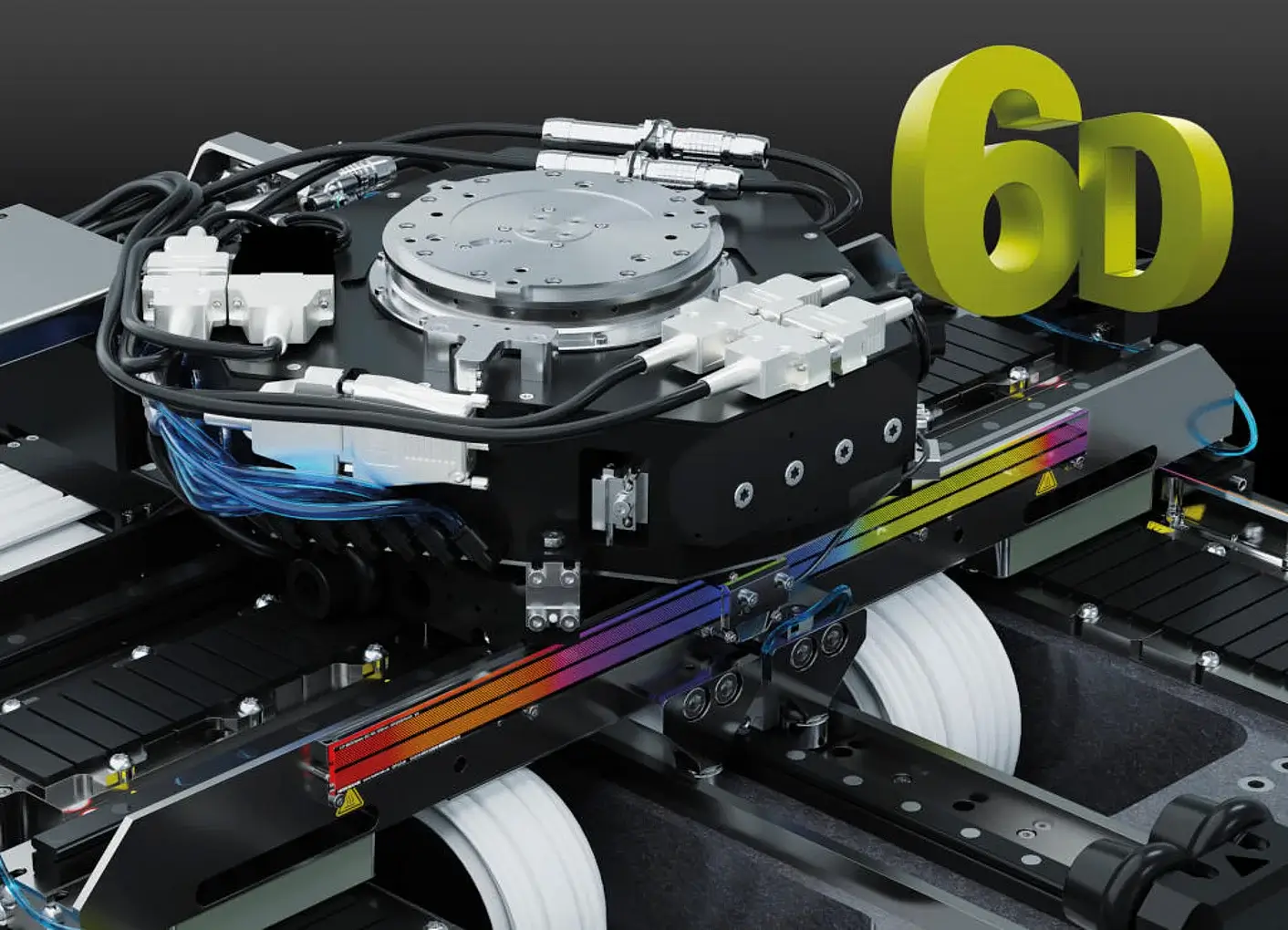

Leverage new 6D setup capabilities on your machine tool. The Model Aided Setup option (MAS) for the HEIDENHAIN TNC7 guides you through the probing process on your touchscreen using a virtual model of the work envelope. A traffic-light indicator shows whether the workpiece position has been fully acquired so that you can save the reference point, allowing you to measure even complex workpieces in little time.

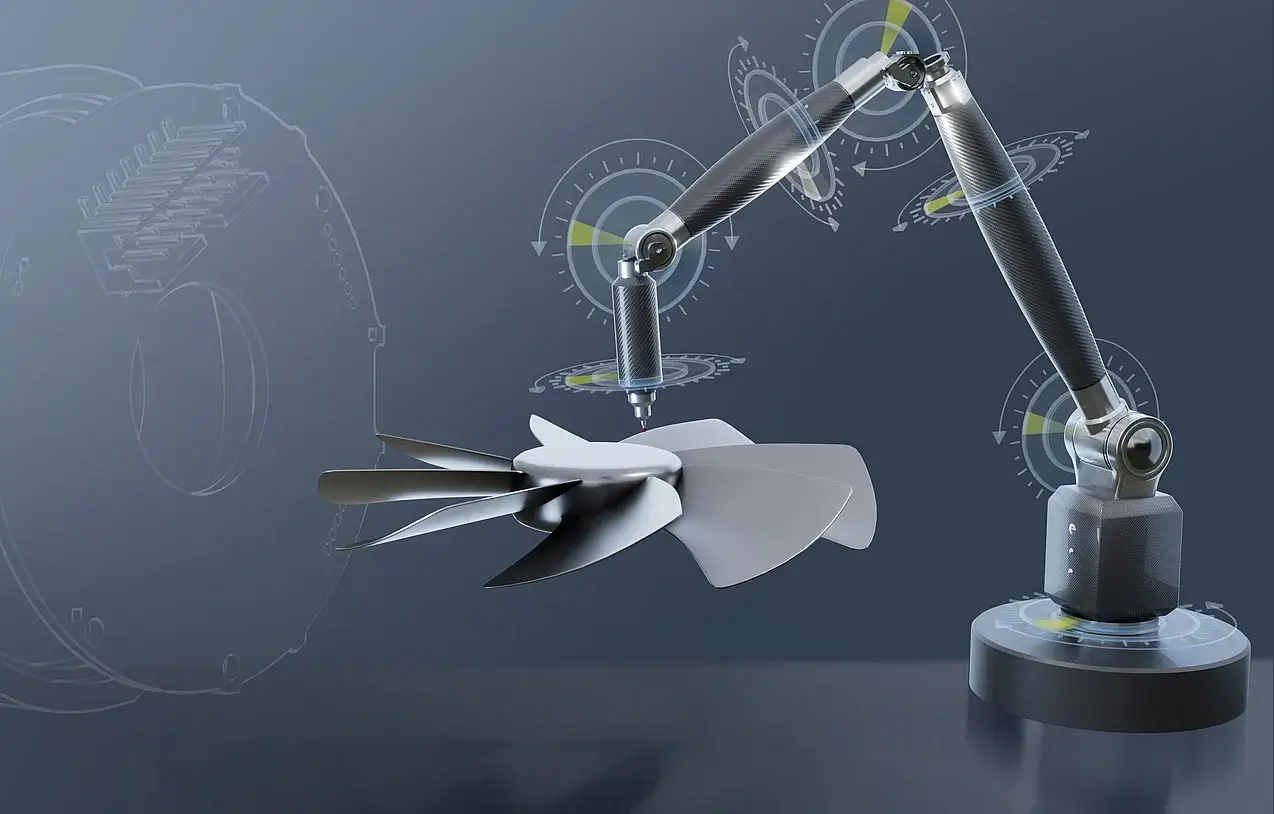

Measuring arms require particularly rigid and compact bearings. Even under off-center loading, the new MRS angle encoder modules from HEIDENHAIN deliver exceptional repeatability. Connecting them via EnDat3 in bus operation gives you high system integration and digital data transmission for less cabling and extensive diagnostics.

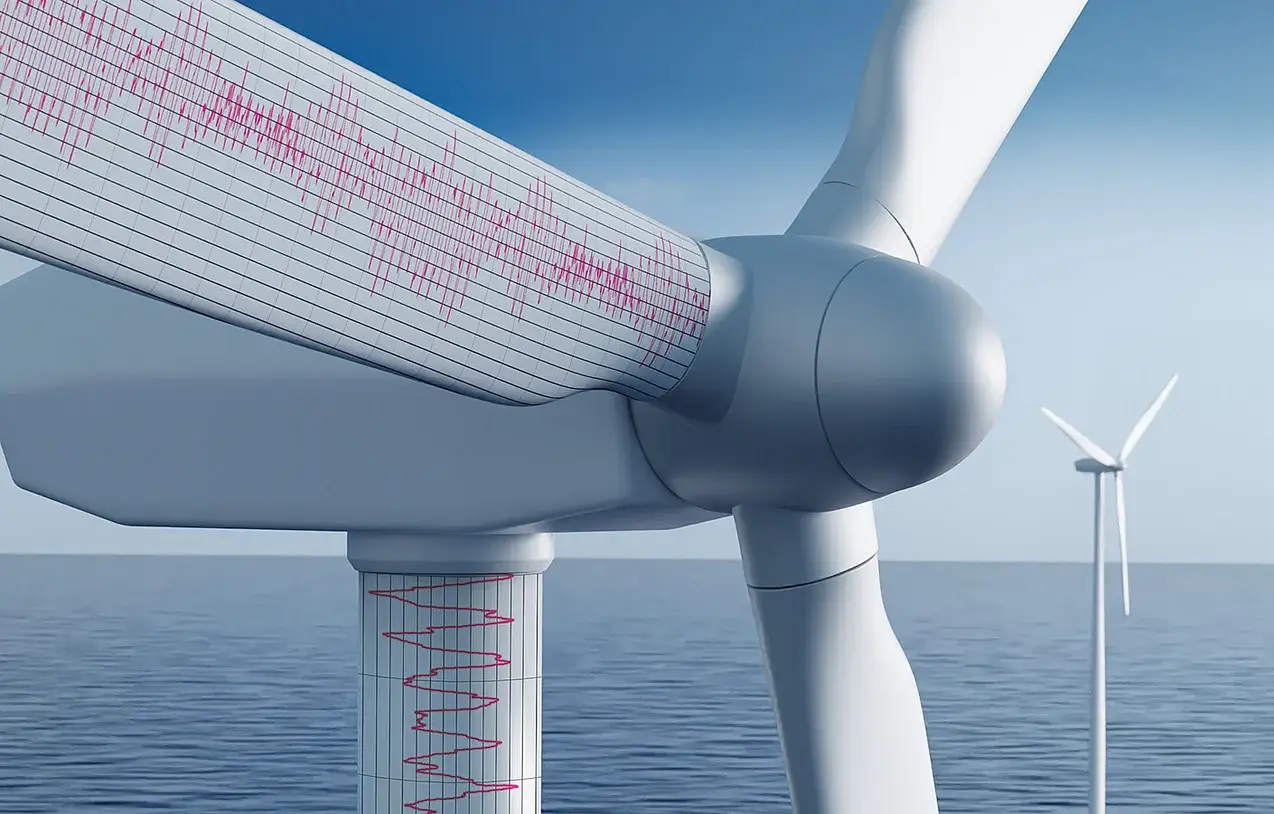

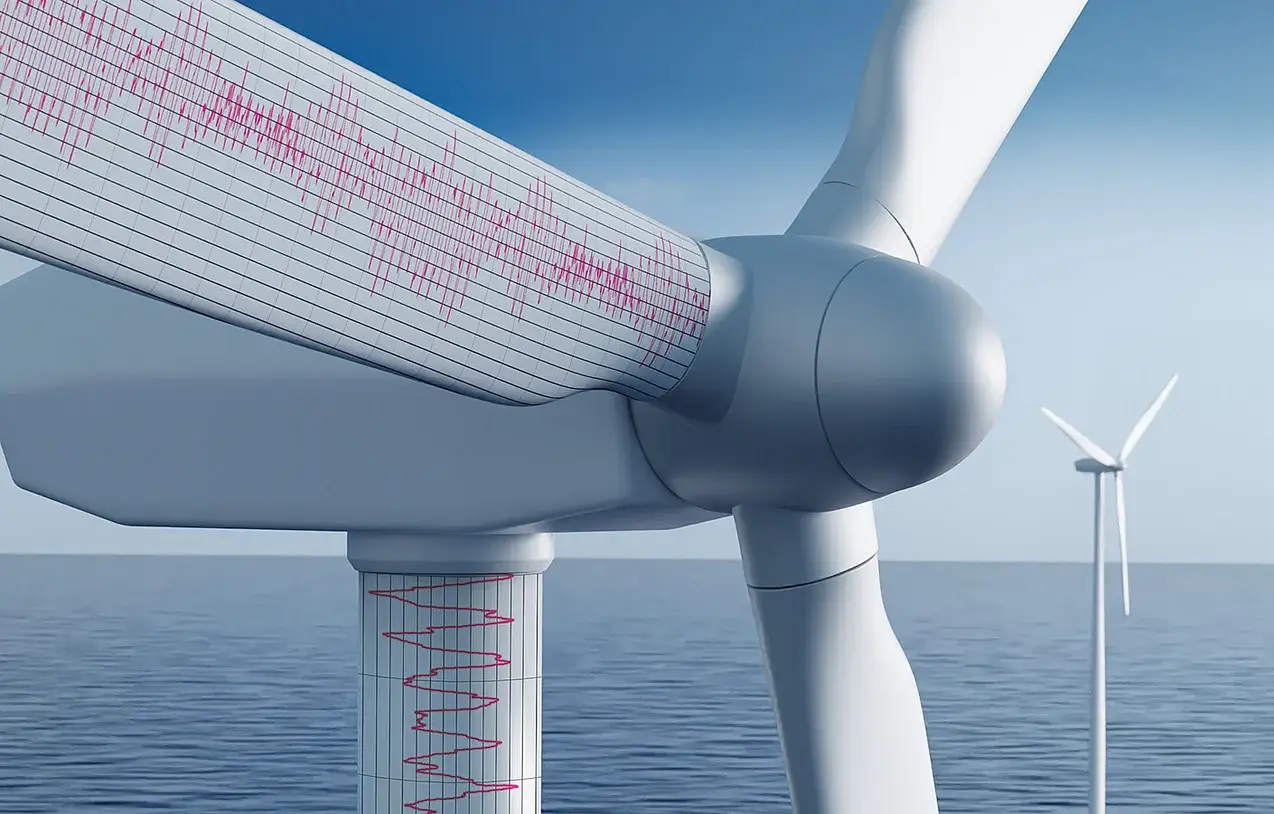

Encoders, sensors and slip rings from HEIDENHAIN and its brands AMO, LEINE LINDE and LTN deliver high-accuracy data about the position, speed and loads acting on a wide variety of wind turbine components. Our solutions support wind-turbine manufacturers and operators in optimizing their systems during the certification, construction, operation and maintenance of everything from the tower to the rotor blades, pitch and azimuth system, gearbox and generator.

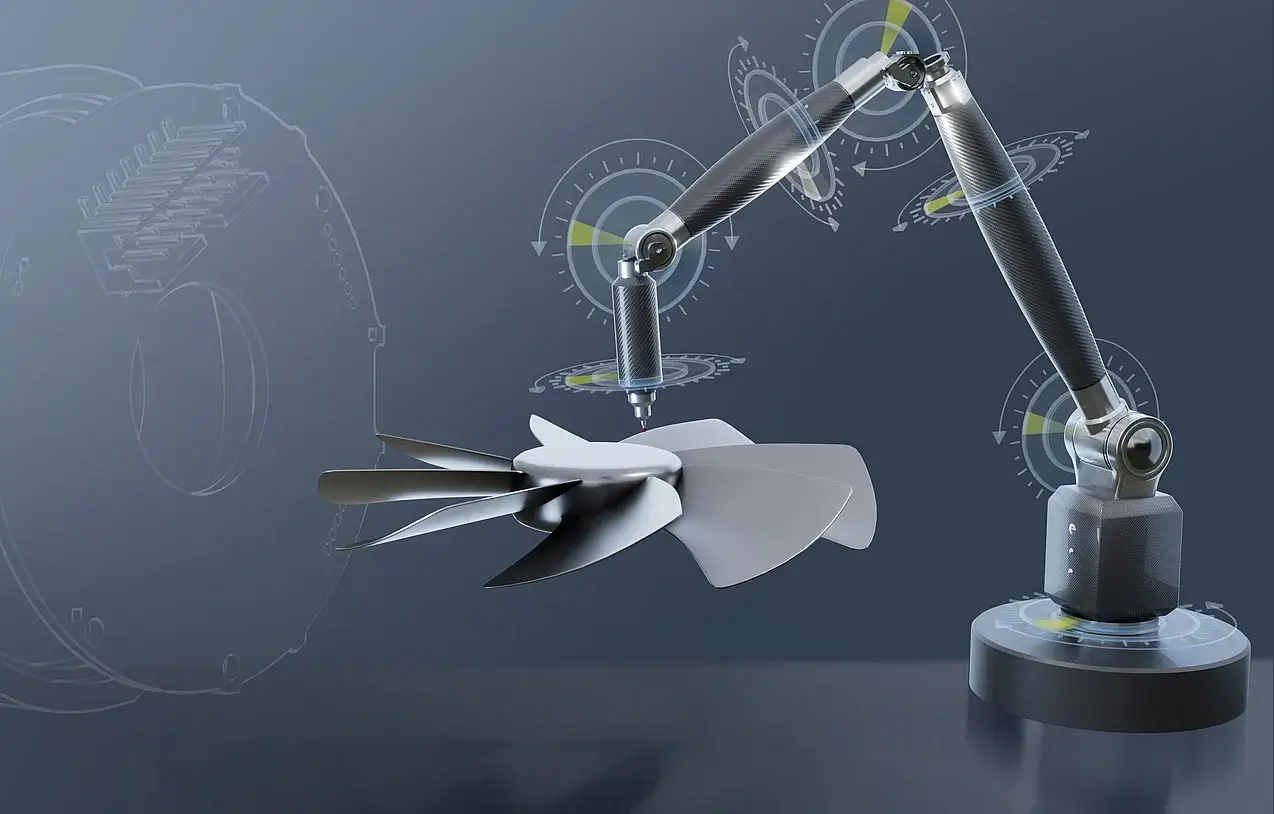

Streamline your robot design and assembly processes while enhancing the accuracy, performance, reliability and service life of your robotics solutions. Find out how in our new e-book “12 ways to optimize your robot design using rotary encoders”. Download it now to discover the benefits of HEIDENHAIN rotary encoders for your robotics applications.

Leverage new 6D setup capabilities on your machine tool. The Model Aided Setup option (MAS) for the HEIDENHAIN TNC7 guides you through the probing process on your touchscreen using a virtual model of the work envelope. A traffic-light indicator shows whether the workpiece position has been fully acquired so that you can save the reference point, allowing you to measure even complex workpieces in little time.

Measuring arms require particularly rigid and compact bearings. Even under off-center loading, the new MRS angle encoder modules from HEIDENHAIN deliver exceptional repeatability. Connecting them via EnDat3 in bus operation gives you high system integration and digital data transmission for less cabling and extensive diagnostics.

Encoders, sensors and slip rings from HEIDENHAIN and its brands AMO, LEINE LINDE and LTN deliver high-accuracy data about the position, speed and loads acting on a wide variety of wind turbine components. Our solutions support wind-turbine manufacturers and operators in optimizing their systems during the certification, construction, operation and maintenance of everything from the tower to the rotor blades, pitch and azimuth system, gearbox and generator.

Streamline your robot design and assembly processes while enhancing the accuracy, performance, reliability and service life of your robotics solutions. Find out how in our new e-book “12 ways to optimize your robot design using rotary encoders”. Download it now to discover the benefits of HEIDENHAIN rotary encoders for your robotics applications.

Leverage new 6D setup capabilities on your machine tool. The Model Aided Setup option (MAS) for the HEIDENHAIN TNC7 guides you through the probing process on your touchscreen using a virtual model of the work envelope. A traffic-light indicator shows whether the workpiece position has been fully acquired so that you can save the reference point, allowing you to measure even complex workpieces in little time.

When striving to enhance the performance and reliability of ...

Selecting the best encoder for your application is crucial ...

HEIDENHAIN North America recently welcomed the Women in Manufacturing ...

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.