Linear encoders for vacuum technology

The word “vacuum” is used to describe an empty space, meaning a volume not filled with air or any other gas. A vacuum is classified as a low, medium, high or ultrahigh vacuum, depending on its purity. ‘

Vacuum technology plays a significant role in many modern production procedures and research tasks. Procedures using vacuum technology have become indispensable in the electronics industry and biotechnology, in thin-film deposition technology, in the development of new materials, and in medicine and analytical technology.

The components used in a vacuum are subject to especially high demands, which of course also affect the encoders necessary for the positioning tasks. The linear encoders designed by HEIDENHAIN specifically for use in high and ultrahigh vacuums satisfy these demands with their specialized design measures:

• Vacuum-compatible PCBs, adhesives and paints reduce the amount of outgassing

• Vented hollow spaces reduce the pumping time

• Temperature resistance permits high heating temperatures

• Doing without ferromagnetic materials increases the process reliability

• Production in a clean room guarantees the highest degree of cleanliness

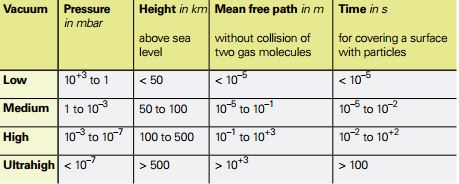

Vacuum classes

When air is removed from an enclosed space, it gets thinner and, as a result, exerts less pressure: a vacuum has been generated. The smaller the amount of air in an enclosed space, i.e. the lower the pressure, the higher the resulting vacuum is classified. There are four classes of vacuum. An atmospheric pressure down to 1 mbar is called a low vacuum; below 1 bar one speaks of a medium vacuum. A vacuum below 0.001 mbar is a high vacuum, and at 0.000 000 1 mbar or less it is called an ultrahigh vacuum.

Vacuum applications

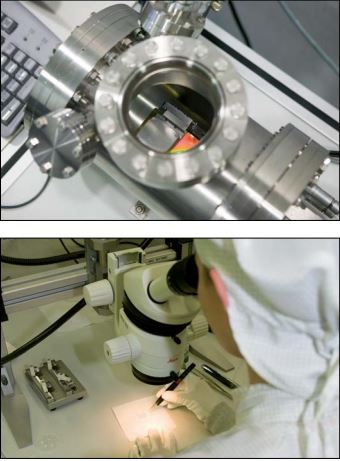

A vacuum in the sense of enclosures free of air and therefore also of suspended particles is required wherever the presence of “foreign” particles must be prevented. In some cases, dimensional measurements are required within the area of a vacuum, for example if very fine structures must be inspected in the submicron range or particles must be split and examined. Widely known applications for linear and angle encoders in a vacuum include electron microscopes, manipulators, multiple actuators, XY tables, e-beam microscopes, wafer inspection in the semiconductor industry, or spectrometer axes for measuring synchrotron radiation.

Requirements for encoders in a vacuum

Requirements for encoders in a vacuum

Most often it is possible to use standard encoders from HEIDENHAIN in a low or medium vacuum within a restricted operating temperature range. Encoders used for applications in a high or ultrahigh vacuum need to fulfill special requirements.

Low amounts of gas exhalation

One precondition for encoders used in vacuum applications is that outgassing is kept to a minimum, since otherwise the pressure in the vacuum chamber might increase excessively. In an ultrahigh vacuum, every component is critical. Some plastics, for example, exhale solvents. Such plastics are contained in printed circuit boards, adhesives, or coating materials and should be completely omitted in devices intended for an ultrahigh vacuum. HEIDENHAIN uses PCBs and adhesives suited to vacuum applications. The usual paints have been replaced by materials appropriate for vacuum technology. In ultrahigh-vacuum environments, the number of components must be kept to a minimum—interface and pulse-shaping electronics must be positioned outside of the vacuum chamber. HEIDENHAIN therefore offers encoders with external interfacing hardware. For high-vacuum applications, one option is to place the interfacing hardware within the vacuum chamber.

Proper ventilation of hollow spaces

To generate a vacuum, the air must be removed from an enclosed space. The time needed for attaining the required low pressure, referred to as “pumping time,” should be kept to a minimum in order to enable the vacuum system to start working as soon as possible. The pumping time is reduced if the air can escape rapidly from the hollow spaces. HEIDENHAIN encoder housings are therefore provided with additional air vents, blind threaded holes are opened, and air vents are drilled into hollow spaces.

To generate a vacuum, the air must be removed from an enclosed space. The time needed for attaining the required low pressure, referred to as “pumping time,” should be kept to a minimum in order to enable the vacuum system to start working as soon as possible. The pumping time is reduced if the air can escape rapidly from the hollow spaces. HEIDENHAIN encoder housings are therefore provided with additional air vents, blind threaded holes are opened, and air vents are drilled into hollow spaces.

No ferromagnetic materials

Depending on the processes in the vacuum chamber, the use of certain materials in the encoders may not be permitted. Ferromagnetic materials must not be used in cathode-ray microscopes for examining microelectronic circuits. Vacuum-technology encoders from HEIDENHAIN are therefore made of non-magnetizable materials.

High resistance to temperature

To further reduce pumping time and attain a high class of vacuum, the vacuum chamber is heated to 100 °C or more. As a result, water molecules clinging to the encoder housing vaporize and can be pumped out more rapidly. Encoders for use in a vacuum must therefore be designed for temperatures of 100 °C and more.

High degree of cleanness

High degree of cleanness

Encoders used in a vacuum chamber must be specially cleansed and exceptionally clean. Most types of lubricants and oils, even fingerprints, emit gases in a vacuum and must be avoided. Otherwise, very fine particles or dust might be set free and, for example, destroy the microelectronic circuits to be examined, or influence the results of experiments. Consequently, our encoders must fulfill specific requirements with respect to cleanliness, the manufacturing process, and proper packaging.

HEIDENHAIN manufactures its vacuum compatible encoders in a clean room. The packaging is also specially designed. The encoder is doubly enclosed and the package is flushed with nitrogen before sealing.

Electrical connection

HEIDENHAIN encoders are equipped with connectors for vacuum housing lead-throughs.

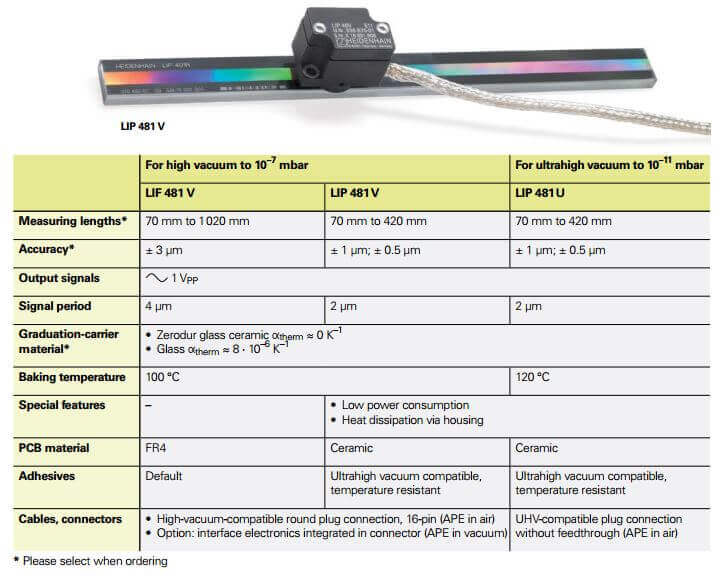

The linear encoders of the LIP and LIF series require interface electronics for signal conversion to 1 VPP. This interface unit is located in the D-sub connector that connects directly with the encoder for highvacuum applications and must be located outside the vacuum chamber for ultrahighvacuum applications. The LIP and LIF for high vacuum are therefore available with two cable versions. The cable between the scanning head and interface electronics can be up to 3 meters in length.

Vacuum-compatible encoders

The vacuum-compatible encoders from HEIDENHAIN were derived from standard units and modified. However, only the original scanning principle, optoelectronic and optical components have remained intact. The housing, PCBs, adhesives and coatings have been adapted to the requirements of the vacuum class.

The following specialized measures characterize HEIDENHAIN encoders for use in a vacuum:

• Non-magnetizable materials (except LED housing)

• Laser inscription instead of labels

• Air vents

• Special coating

• Production in a clean room

• Specialized cleaning and packaging

• Cable with PTFE insulation and silverplated copper braiding