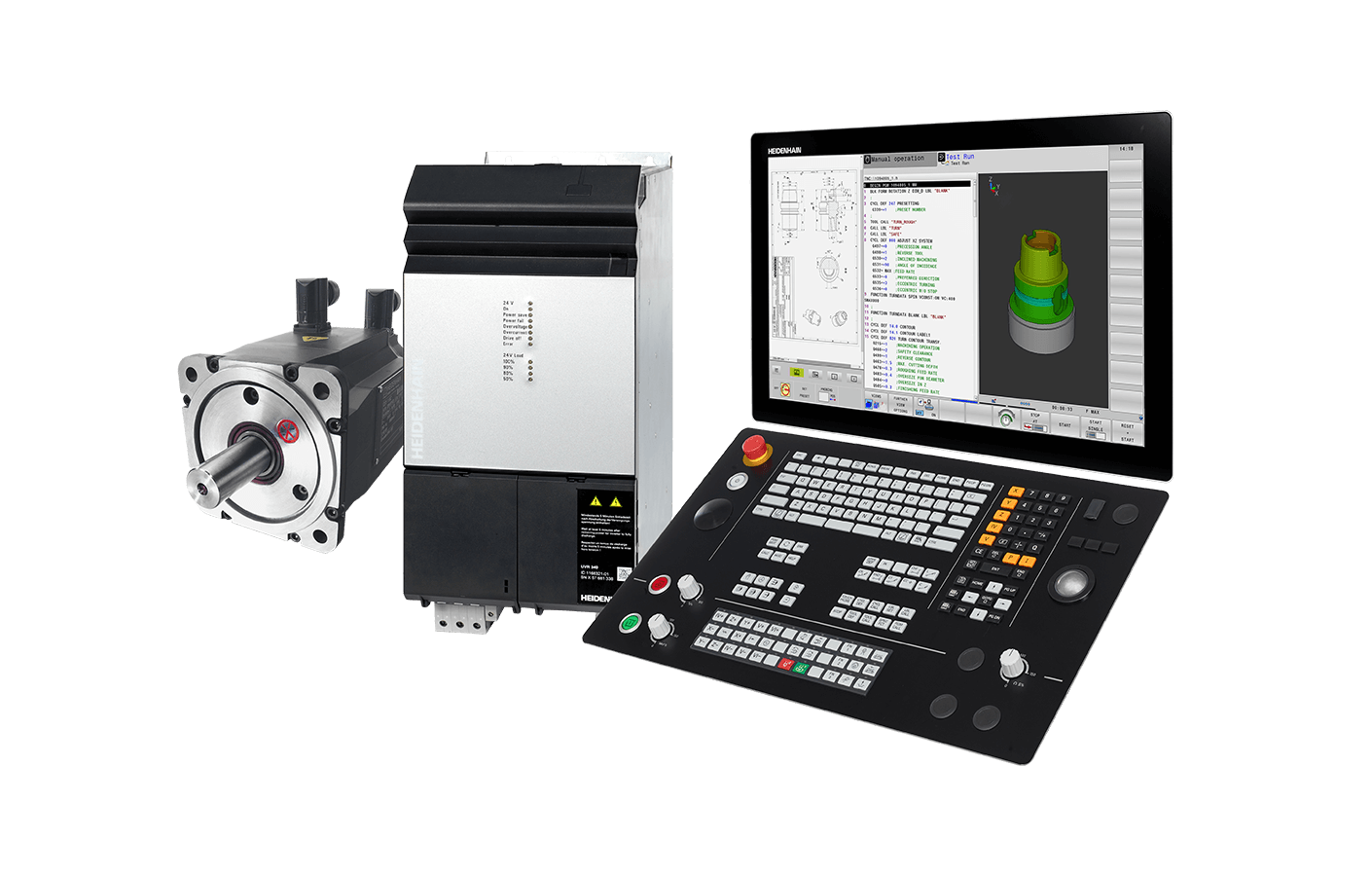

Drive systems

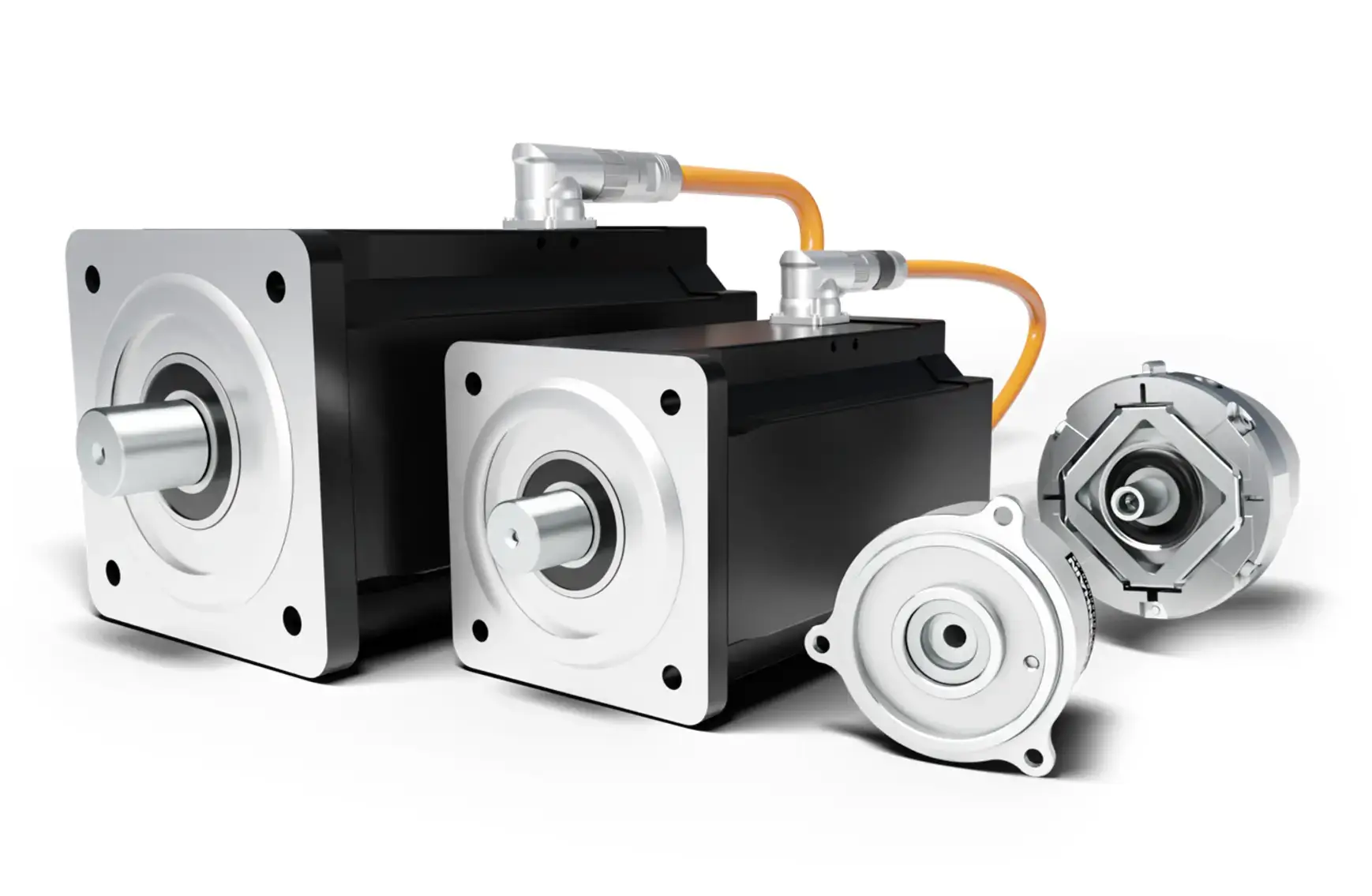

High-performance motors and application-tailored encoders for motor feedback deliver the motion and dynamic performance needed in machine tools, automation solutions, elevators, printing machines, and more. HEIDENHAIN and ETEL provide motors and complex motion systems for high-accuracy applications in industries such as semiconductors and electronics. Machine and automated system manufacturers will find a comprehensive selection of tailored encoders for a wide of variety of motors, applications, and requirements from HEIDENHAIN, AMO, RSF, and RENCO.

Encoders for servomotors

HEIDENHAIN offers a wide range of rotary encoders and angle encoders for servomotor control, empowering you to handle nearly any positioning and control task, irrespective of the following factors:

- Your application’s mechanical requirements

- Your interface technology

- Your accuracy requirements

- Your desired level of safety

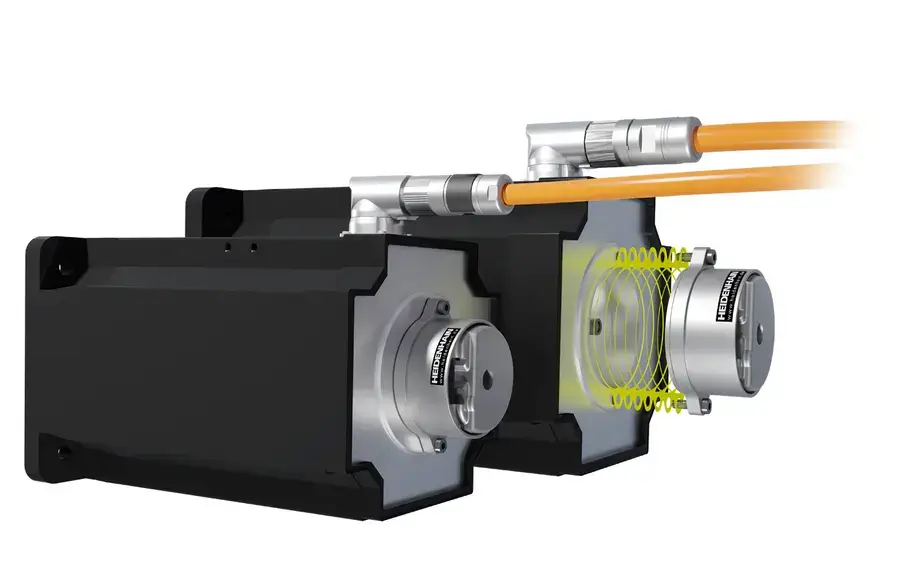

These encoders can be connected with commonly available cables and connectors, but also with our innovate HMC 6 single-cable solutions for the EnDat 2 interface, or HMC 2 for the state-of-the-art EnDat 3 interface.

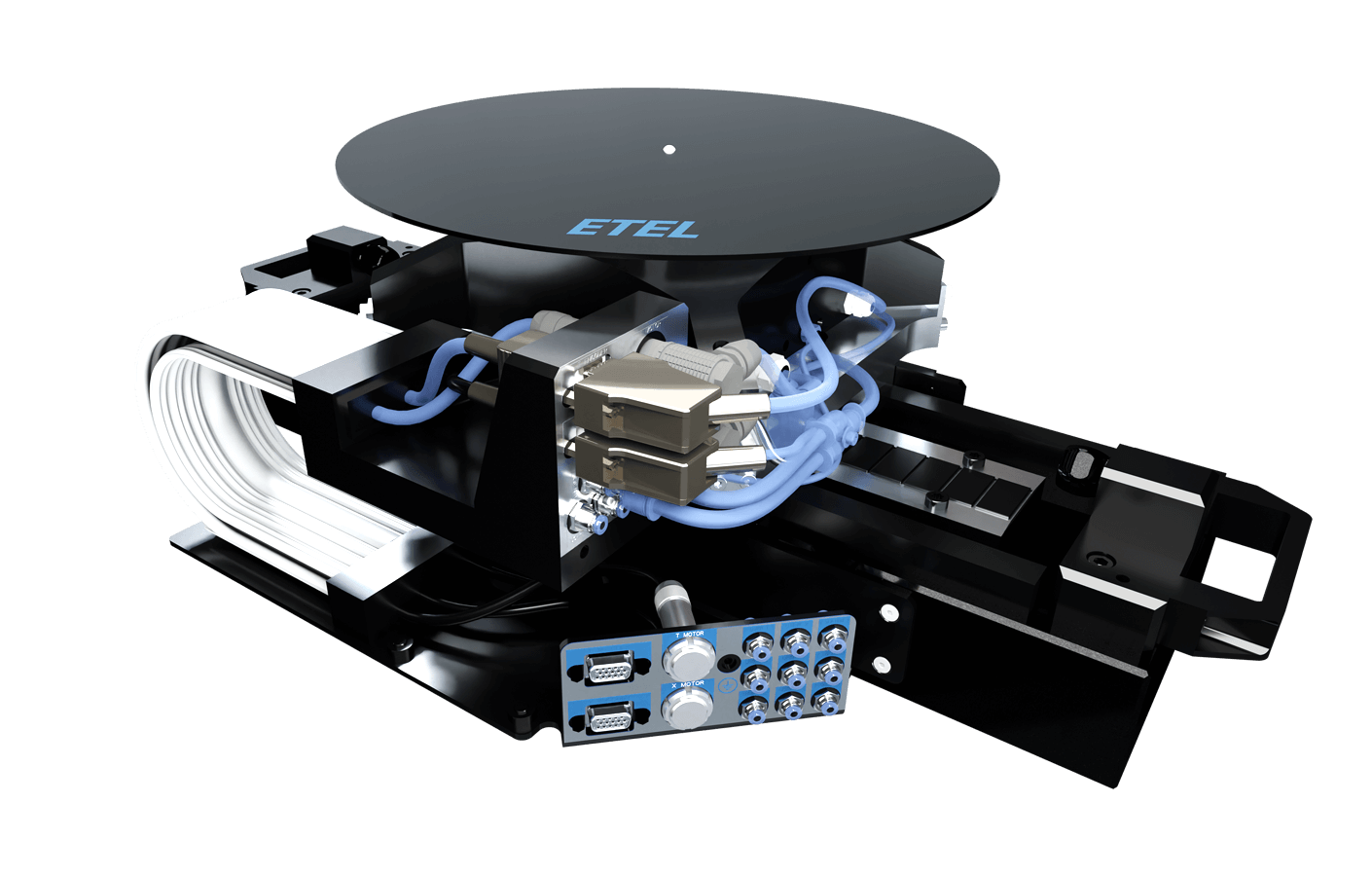

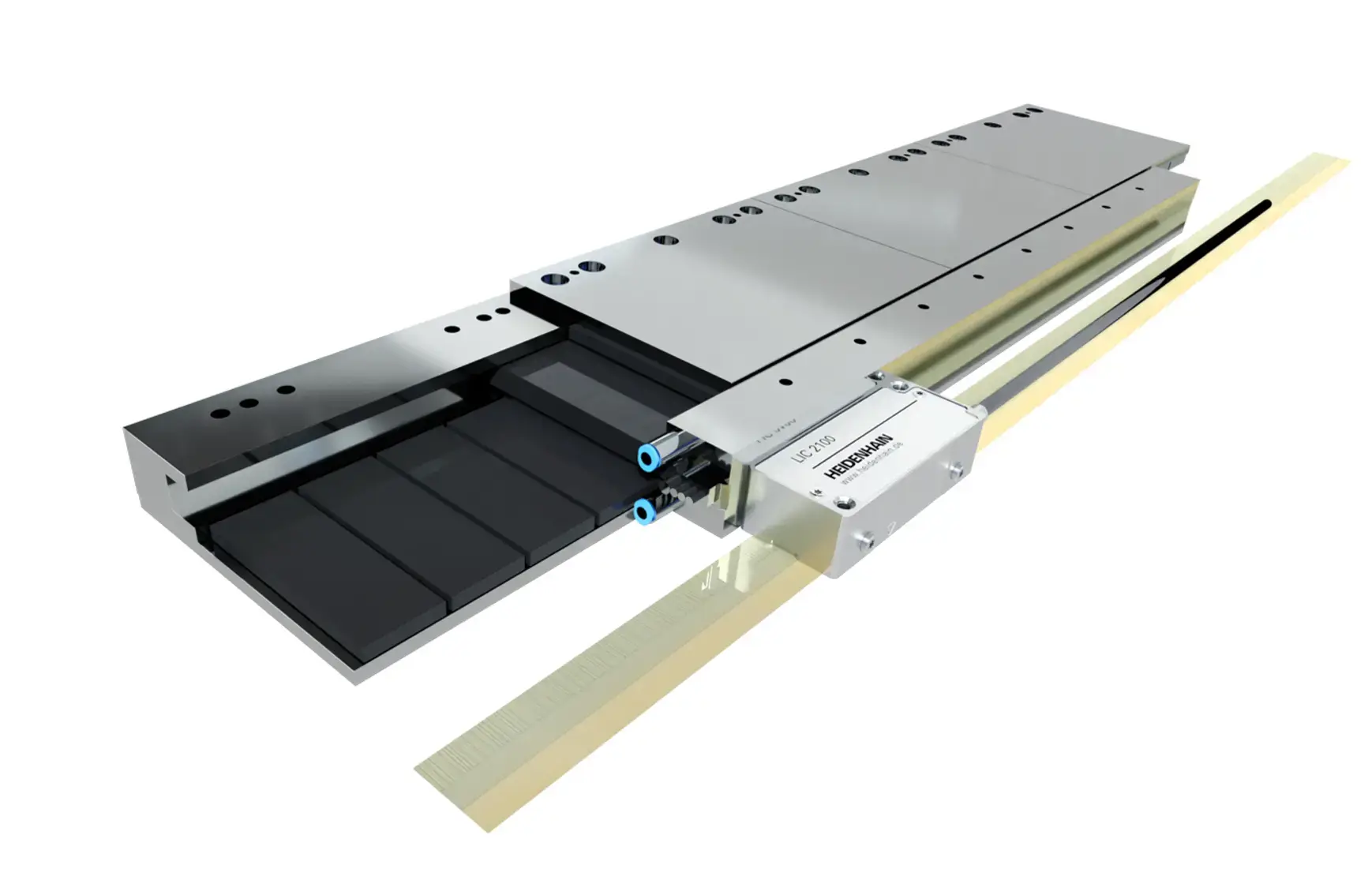

Encoders for linear motors

Linear motors provide numerous benefits such as high dynamic performance, reliability, and longevity. Position feedback is provided by linear encoders exhibiting these same characterstics.

Sealed linear encoders, with their resistance to dust, chips, and cooling lubricant, are ideal for machine tools. Exposed linear encoders are available for direct drive motors, especially in measuring equipment. Modular solutions offer nearly unlimited flexiblity for installation in a wide variety of applications.

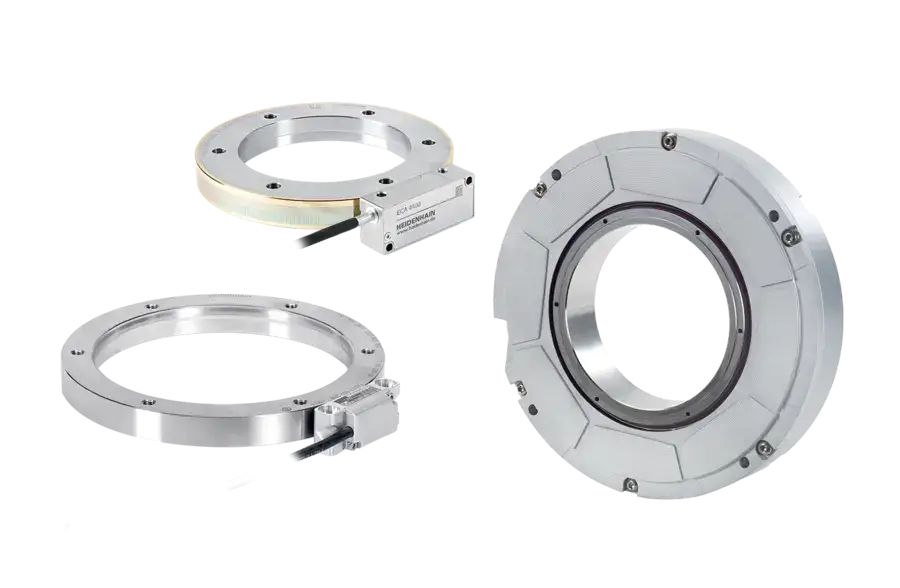

Encoders for torque motors

Our product portfolio includes rotary encoders and modular angle encoders specifically for motors with large hollow shafts. Scale-tape solutions can be used on large motor shafts nearly without limits. Rotary encoders with a scale drum are available for hollow shaft diameters of up to 180 mm.

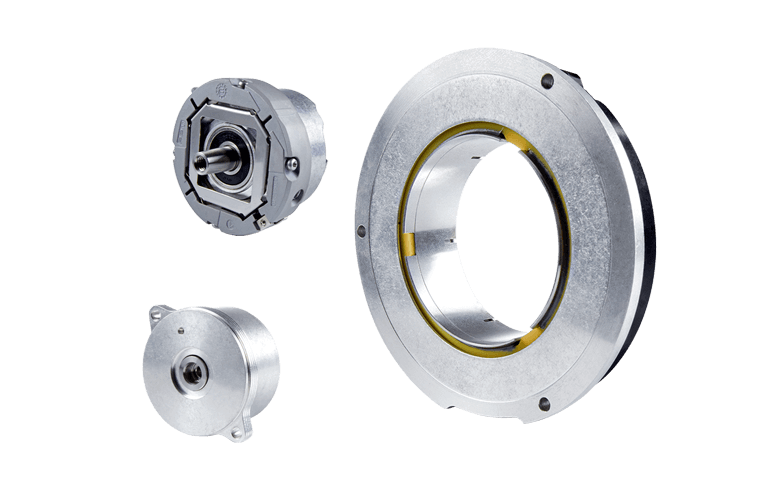

Encoders for stepper and BLDC motors

The new RENCO rotary encoder generation, featuring a resolution of up to 40 000 measuring steps per revolution, is ideal as a motor feedback system for stepper motors in closed loop operation and BLDC motors. Their strengths are:

- Fast and easy installation thanks to a built-in mounting aid

- Electronic adjustment of the motor commutation signals at the push of a button

- Dependable operation thanks to monitoring and diagnostic functions

- Exact rotor position measurement for BLDC motors

- Very accurate UVW track sequence specification for electronic commutation on motors with up to 32 pole pairs

For very tight installation spaces we offer the RENCO R35iL. With a height of just 8.6 mm, it is one of the flattest rotary encoders currently on the market.