Robotics

Robots have become an indispensable part of everyday life. As fast and tireless helpers, they take on otherwise monotonous and strenuous human tasks in manufacturing and logistics, including assembly processes, the transport of goods, and heavy lifting. Robots are also used in ever more demanding fields, including large component assembly for aircraft fuselages or as cobots in direct collaboration with humans. HEIDENHAIN, AMO, NUMERIK JENA, RENCO, and RSF offer optimal encoders for all robotics applications.

Dual encoders and secondary encoders for greater accuracy in advanced robotics

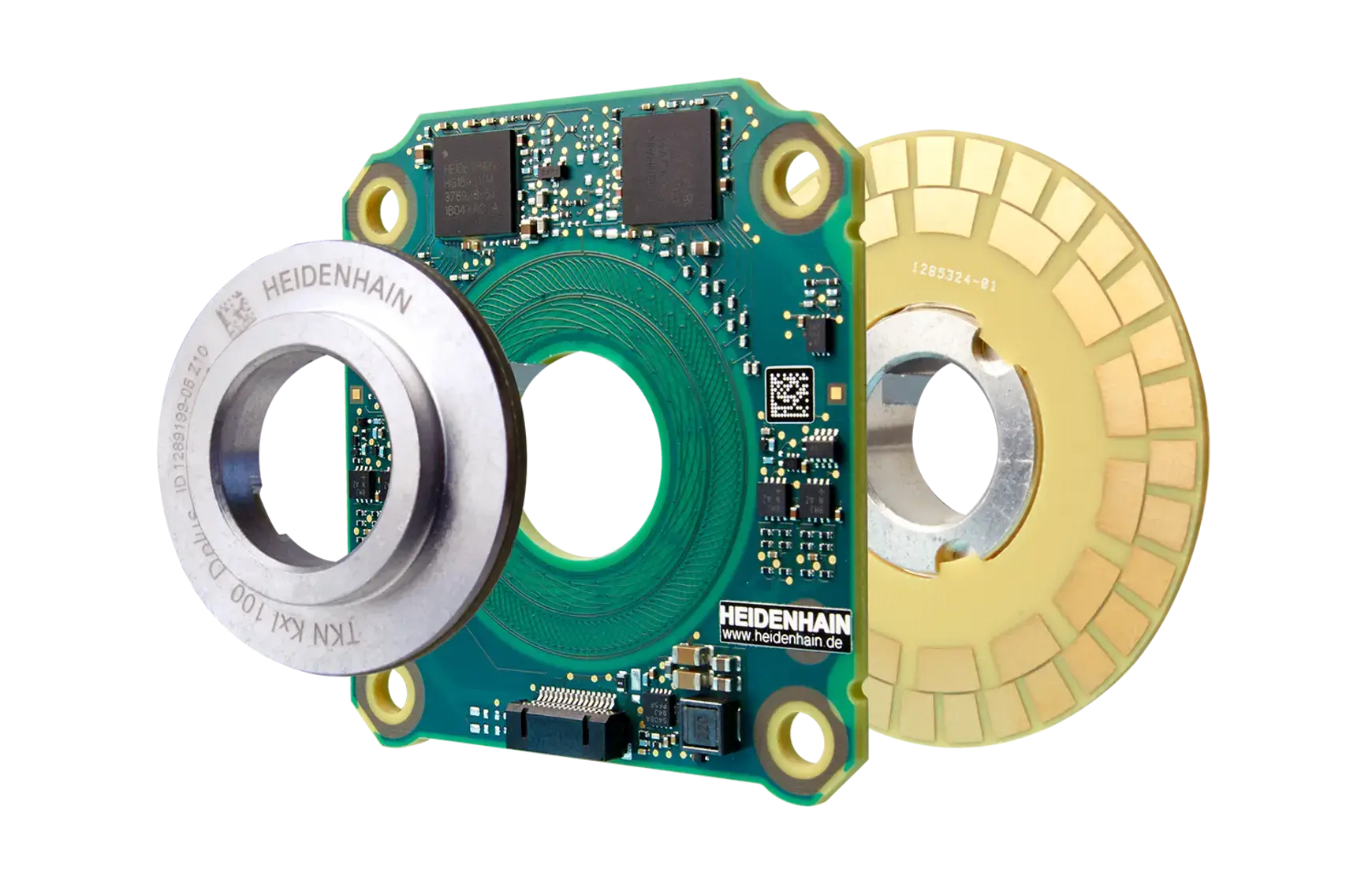

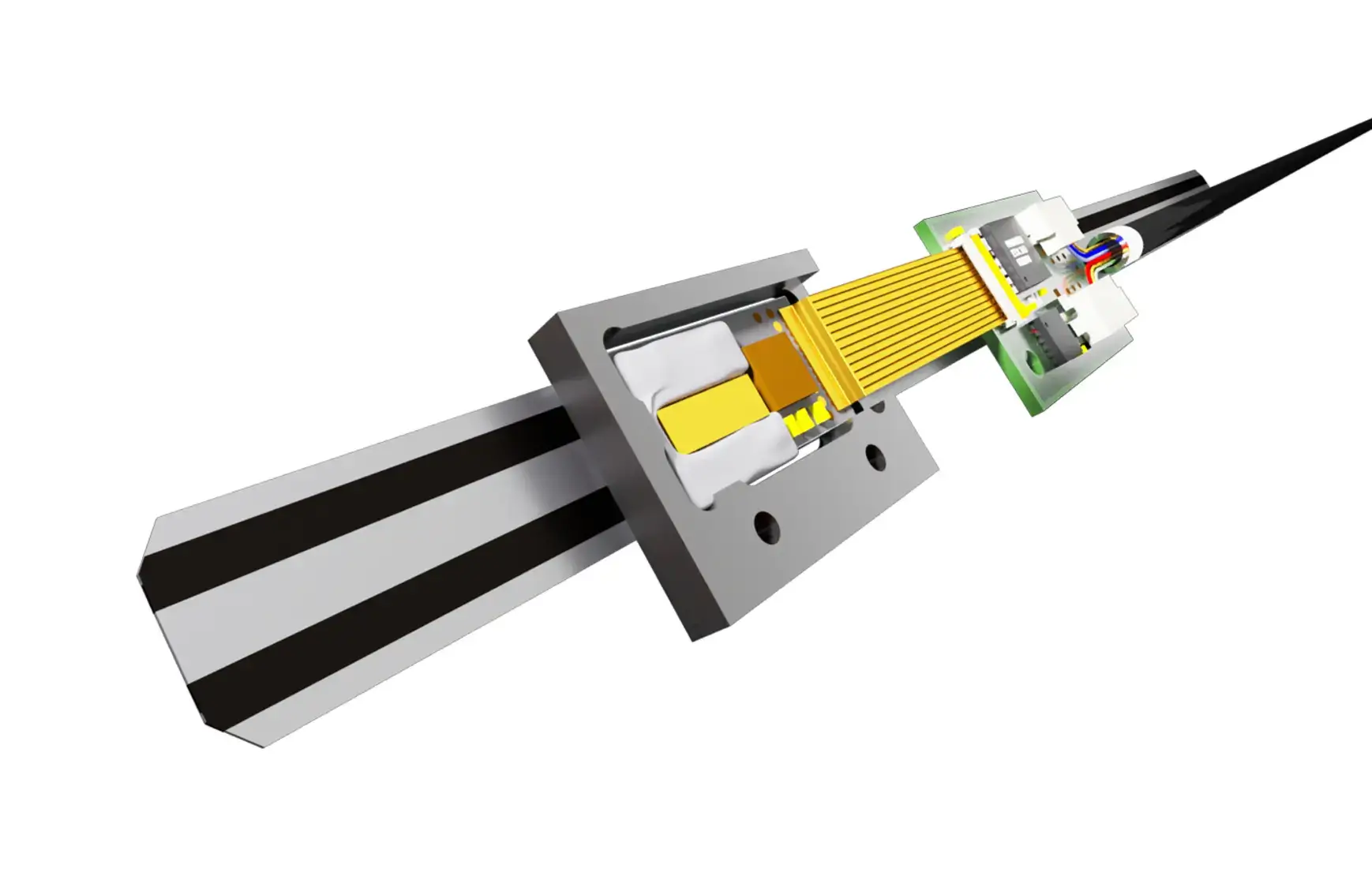

Motor feedback and position measurement all in one

The KCI 120 Dplus dual encoder provides motor feedback and position measurement in a single device. Installed downstream from the gear system, it enables the compensation of design-related inaccuracies in dynamic robots, such as joint elasticity, zero-position error, reversal error, and machining effects. The encoder’s purely serial EnDat 2.2 interface with functional safety permits deployment in applications such as human-robot collaboration.

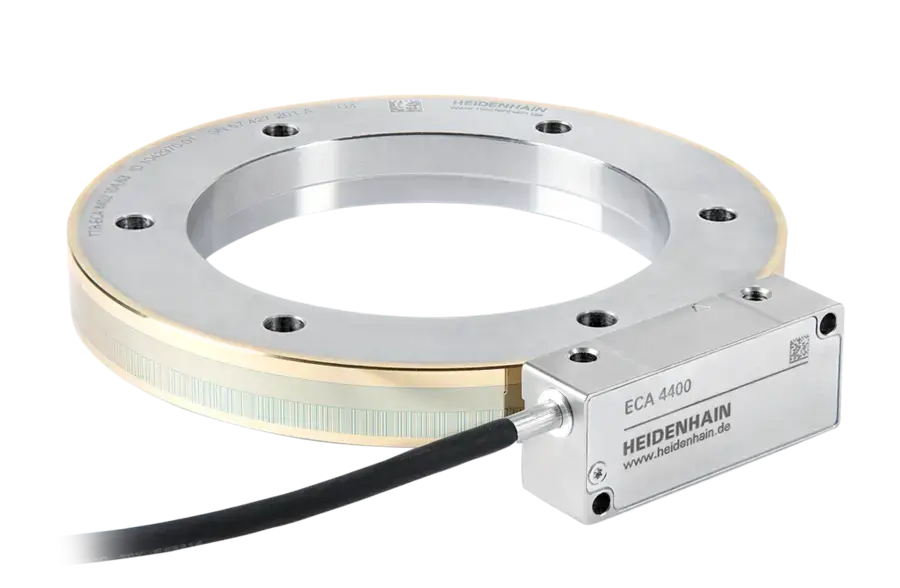

Secondary encoders for additional accuracy

The absolute position accuracy of your robots can also be improved by adding a high-accuracy angle encoder to each axis. Mounted downstream from the gear system, secondary encoders measure the actual position of each robot joint. We offer modular encoder solutions for this purpose, such as the HEIDENHAIN ECA 4000 with optical scanning, the AMO WMRA angle encoder system, and angle encoders from RSF. These encoders are well suited to large shaft diameters and challenging installation requirements, making them ideal as secondary encoders.

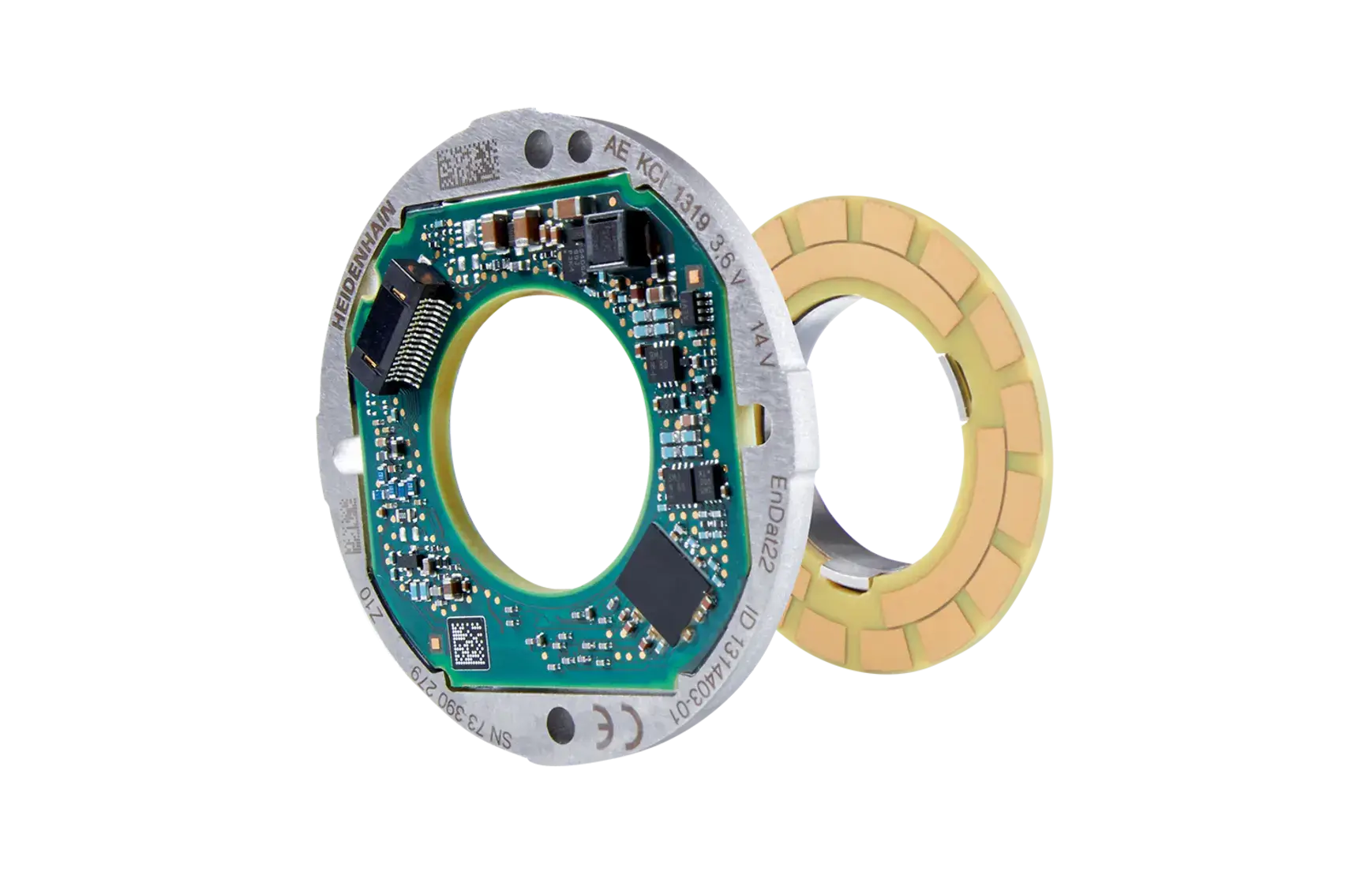

Safety-related rotary encoders for conventional motor control

KCI 1300 and KBI 1300 for compact robot motors

The KCI 1300 and KBI 1300 rotary encoders deliver inductive scanning capability in a low-weight, low-profile design, making them ideal for compact servomotors in robots. Their reliable inductive scanning method makes them insensitive to contamination and magnetic fields. The diagnostic data they provide enable condition monitoring, including motor monitoring via an external temperature sensor. Consisting of just a scanning unit and a screw-fastened circular scale or a disk/hub assembly press-fit to the motor shaft, the KCI 1300 and KBI 1300 are easy to install thanks to their wide mounting tolerances.

The new RENCO generation: simply reliable

The new generation of RENCO R35i and R35iL incremental rotary encoders feature 40 000 measuring steps per revolution, making them an excellent motor feedback system for stepper and BLDC motors in robotics applications such as automated guided vehicles. For very limited installation space, the R35iL features a low 8.6 mm profile, giving it one of the smallest footprints on the market. Here are your benefits:

- Fast and easy mounting thanks to an integrated mounting aid

- Electronic adjustment of the commutuation signals at the push of a button

- Safe and reliable operation thanks to monitoring and diagnostic functions never before available in incremental encoders

- Exact measurement of the rotor position of BLDC motors and very accurately specified UVW track sequence for the electronic commutation of motors with up to 32 pole pairs

Extremely short linear encoders for the gripper

Measure lengths where space is limited

With the LIKselect, NUMERIK JENA offers an exposed linear encoder specifically designed for limited installation space and high accuracy requirements. The LIKselect also enables a very individual, customer-specific design. This means that LIKselect encoders are especially well suited for use in robot grippers.

Precise linear robotic mobility

Linear encoders for long-range mobility

During the machining and assembly of very large aerospace or energy-sector components, industrial robots need to access all operating positions along the length of a fuselage or large composite part. Position measurement provided by a linear encoder can compensate for thermal error and other effects on the feed mechanism that cannot be measured by a rotary encoder and the ball screw pitch. For high-accuracy robot positioning with a linear motor, ideal solutions are the up to 30 m long linear encoders from HEIDENHAIN, modular unlimited-length scale tape solutions from AMO, or customized linear encoders from RSF.