MANUALplus contouring control

Proven and advanced technology

- 10 control loops, including up to 6 spindles

- Multi-touch screen

- Programming: teach-in, G codes, smart.Turn (option)

- Extensive cycle packages for probing and machining

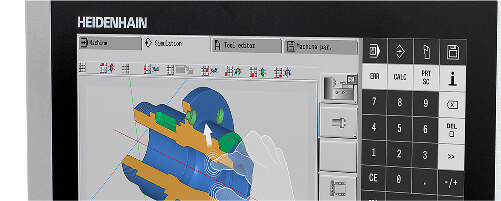

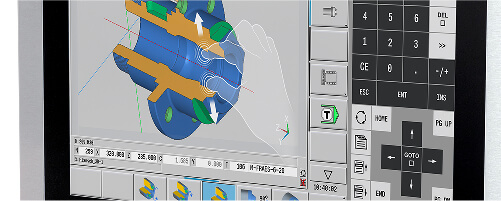

- High-resolution and highly realistic 3D simulation graphics

- Fast block processing time (3 ms)

Manual operation

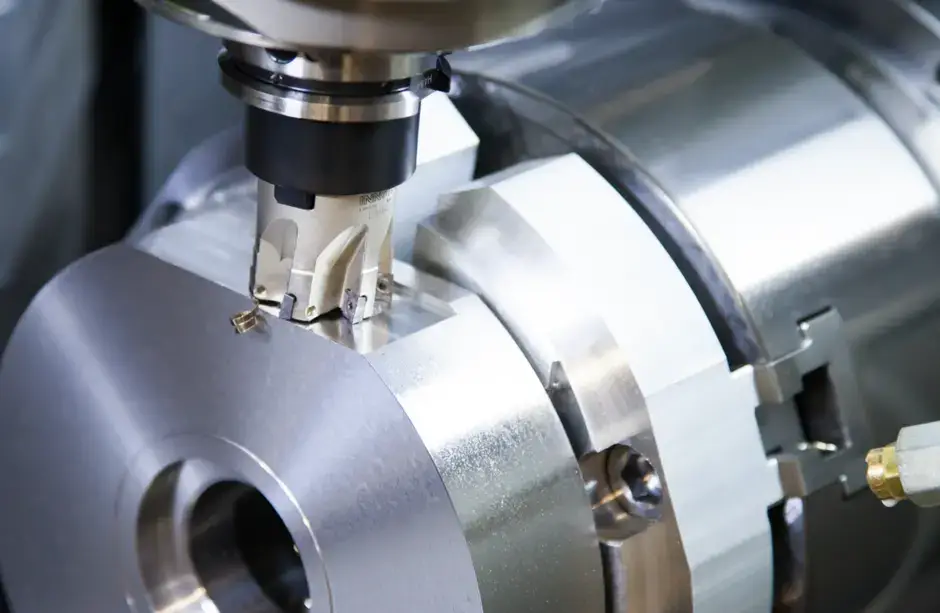

This versatile contouring control accommodates the operation of conventional lathes and CNC machines. In manual mode, the machine can be conventionally operated with electronic handwheels. It also features the full range of functions of a CNC turning control.

Handy teach-in mode

In teach-in mode, manual machining operations and cycles are performed step-by-step and saved for future parts. As a result, conventional lathe operators without programming expertise can easily get started with CNC-controlled machines.

Multi-touch operation

Having a touchscreen makes operation particularly easy: you use gestures to zoom and rotate the simulation graphics; swipe to switch between soft key rows; and navigate through programs, tables, and menus. Intuitive touchscreen operation takes you there faster.

Realistic simulations

The detailed simulation graphics enable a precise and realistic machining preview prior to machining, revealing whether the program has all required entries, whether machining operations will run smoothly, and whether surfaces will attain the desired quality.

Automatic programming

The TURN PLUS automatic programming function is the fastest route from a design drawing to the finished workpiece. After the contours of the workpiece blank and finished part have been entered, all that remains is to select the material and workholding equipment. TURN PLUS automatically takes care of the rest at the push of a button.

Flexible operating design

The degree of automation can be increased as desired, from simple machining to full CNC capability. The intuitive operating interface of the MANUALplus 620 supports the relevant operating modes. Support images and informative dialog guidance simplify programming. Contours can be programmed interactively or imported as DXF files.

Application-oriented design

Click the plus signs to learn more about the product.

The intuitive and clearly structured user interface make simple operation and optimal orientation possible

Gesture control makes it very easy to zoom and rotate simulation graphics as well as to navigate through programs, tables, or menus

Easily automate manual machining

The MANUALplus 620 is a compact and versatile contouring control particularly well suited to cycle-controlled lathes. It optimally combines the convenient operation of conventional lathes with the benefits of CNC-controlled machines. The control can be flexibly adapted to the needs of the company, no matter how complex its workpieces are. The MANUALplus 620 features easy operation and programming along with a wide performance range.

Easy connectivity

Easy data usage, time-saving workflows, and transparent processes: Connected Machining enables optimal connection to digital job and data management solutions in a manufacturing context. With the Connected Machining package of functions, HEIDENHAIN controls can be perfectly integrated into process chains through future-ready digital interfaces and flexible operating designs, thus optimizing the transfer of knowledge within your company. Connected Machining incorporates HEIDENHAIN controls into the purely digital job management landscape of a production network and places the user at the center of the digital job management process.

Connected Machining delivers:

- Easy data usage

- Time-saving workflows

- Transparent processes