TNC7 contouring control

Intuitive, task-focused and customizable

- 24 control loops, four of which are for spindles

- Very high operating speed and fluid, intuitive multi-touch operation

- Milling, turning and grinding operations

- Intuitive machine setup with smart probing functions

- Graphically supported workholding alignment

- Fast block-processing time (0.5 ms)

- High-end performance for perfect surfaces and exceptional accuracy

- Integrated process monitoring

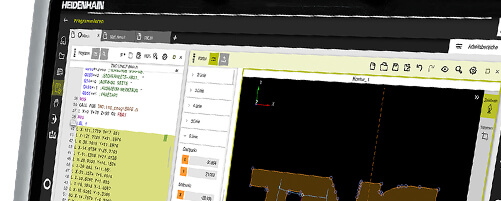

Customized user interface

The TNC7 supports users in every situation, including programming, machine setup and part measurement. The screen contents can be easily adapted to the given situation, thereby providing all information and functionality exactly where it is needed. And a special Dark mode feature simplifies operation under low ambient light.

Smart programming

The TNC7 supplements familiar Klartext programming with smart functions. The newly developed graphical programming feature allows the user to draw contours directly on the touchscreen. The TNC7 then converts the resulting drawing into a Klartext program. Older Klartext programs can also be easily modified.

Familiar surroundings

Operating elements such as the TNC keyboard are still used on the TNC7, offering excellent ergonomics even for prolonged work. Older NC programs can continue to be used. Working with the TNC7 is made simpler by a guided introduction to its new functions.

Task-focused support

The TNC7 provides intelligently designed solutions, including a vast package of cycles, smart probing functions and graphical guidance for 6D aligning your workholding and workpieces. Perfect visualization of the machined part and work envelope deliver great convenience to your workday, as do numerous new functions and work methods.

Reliable processes

The new Process Monitoring function built into the TNC7 reliably detects irregularities in the machining process and ensures high process quality. The user can adapt this monitoring capability through simple Klartext syntax and an intuitive user interface.

Predictive protection

The Component Monitoring feature of the TNC7 can protect the spindle bearing from overloading or detect increased component wear in the drive train, all while the machine is running. It also provides valuable data for predictive maintenance and evaluation of the process capability.

Sustainable manufacturing with the TNC7

Software options for 6D setup support allow TNC7 users to probe fixtures and workpieces up to five times faster, thus saving considerable time and energy. Thanks to the non-stop monitoring of components and processes, along with extensive simulation capabilities, the TNC7 increases the process reliability of machine tools.

Practical design

Click the plus signs to learn more about the product.

The screen workspaces can be adapted to individual needs and wishes. This includes, for example, favorites for NC functions, status notifications, and files, a home menu for getting started quickly, and personalized settings in the user administration function.

Smooth and highly dynamic touchscreen operation ensures zero reaction delay with simple gestures such as are commonly used on mobile devices.

There are many options for creating a program at the control; a new one is the intuitive contour programming via symbolic gestures on the touchscreen. Klartext remains the main format for files and exporting, meaning that existing NC programs can continue to be used.

The newly developed keyboard features an improved mechanical design, including an optimized key resistance. The improved ergonomics simplify your work and perfectly complement touch operation on the screen.

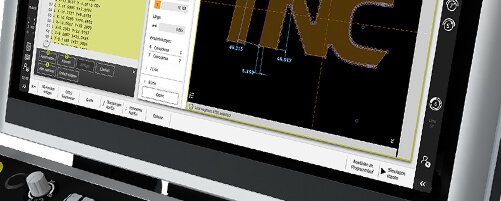

Graphical programming

Create an NC program the smart way

Create NC programs quickly and easily: The graphical programming feature allows users to work directly within the part drawing on the touchscreen. The TNC7 then converts the drawing into a Klartext program. Changes made to the Klartext program can be dragged and dropped in order to create an updated drawing with all relevant dimensions.

Intuitive setup

Advanced collision protection for workholding equipment

The TNC7 has taken Dynamic Collision Monitoring (DCM) to the next generation. In this new level of CNC control, DCM prevents collisions not only between tools and machine components but also between tools and workholding equipment. The graphically supported locating process merely requires an accurate 3D model of the fixture. The TNC7 then interactively guides the user through the entire process, allowing him to locate the position of the fixture on the machine table in no time using intelligent probing functions.

TNC Component Monitoring

Protect your machine from overloading

TNC Component Monitoring is a toolbox for machine manufacturers that allows them to reliably implement extensive monitoring functions in their machines. These functions include real-time process monitoring for preventing severe overloading, and data collection for predicting mechanical wear.

TNC Process Monitoring

Reliably achieve the desired results

The new Process Monitoring function helps users reliably achieve the desired machining results with the TNC7. The control detects any deviations from a reference machining run, thereby monitoring all quality aspects of serial production, including the machine setup, the machining process and the finished part. No extra sensors or external computers are needed.

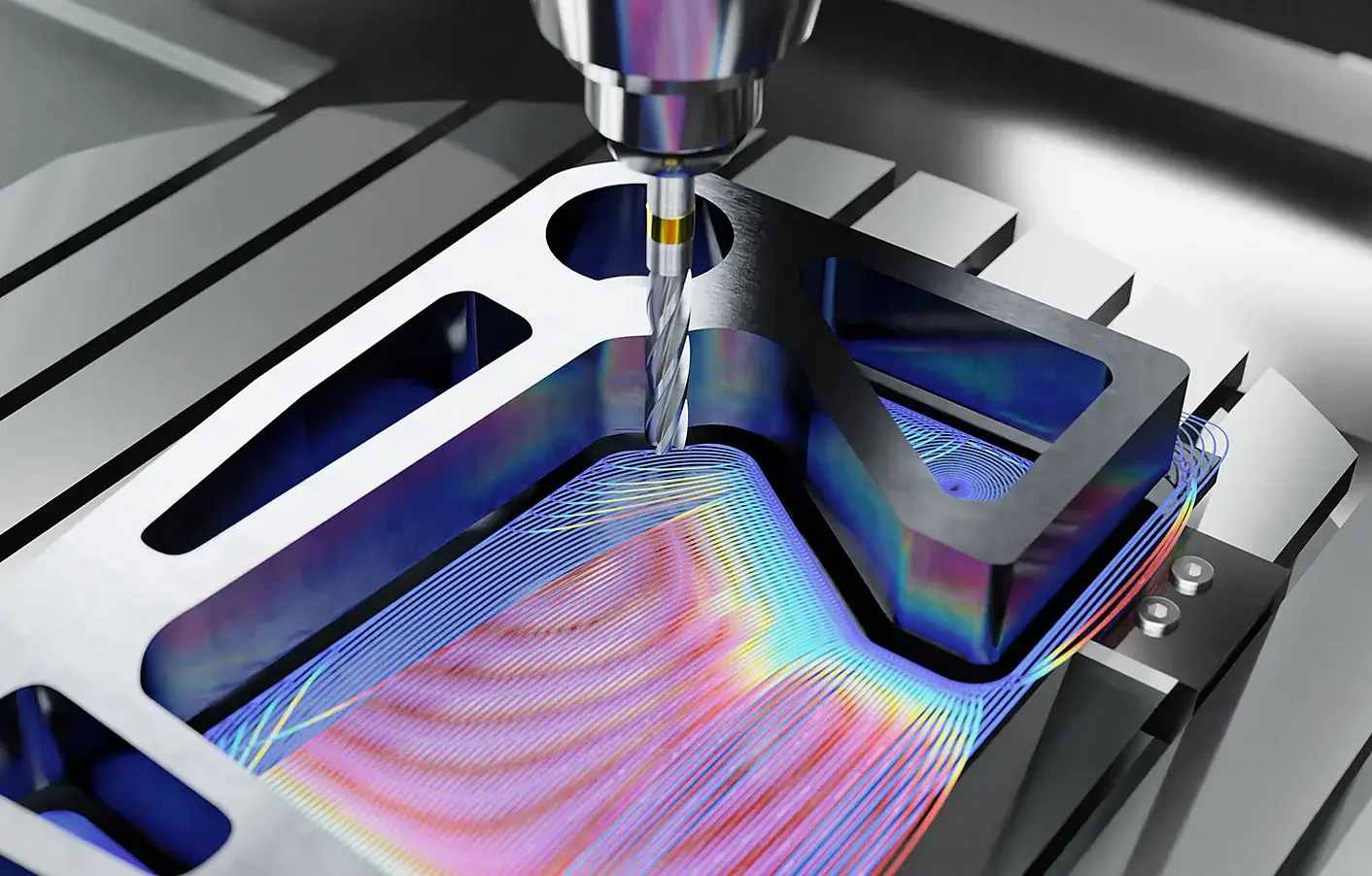

Optimized Contour Milling (OCM)

Always mill with optimum cutting parameters

OCM offers numerous possibilities for reliable, low-wear machining with constant process conditions. Users simply define the contour. The control then automatically calculates the best trochoidal milling strategy. This lets you use highly efficient trochoidal milling processes for a much wider range of workpieces, letting you mill with greater productivity and less tool wear.