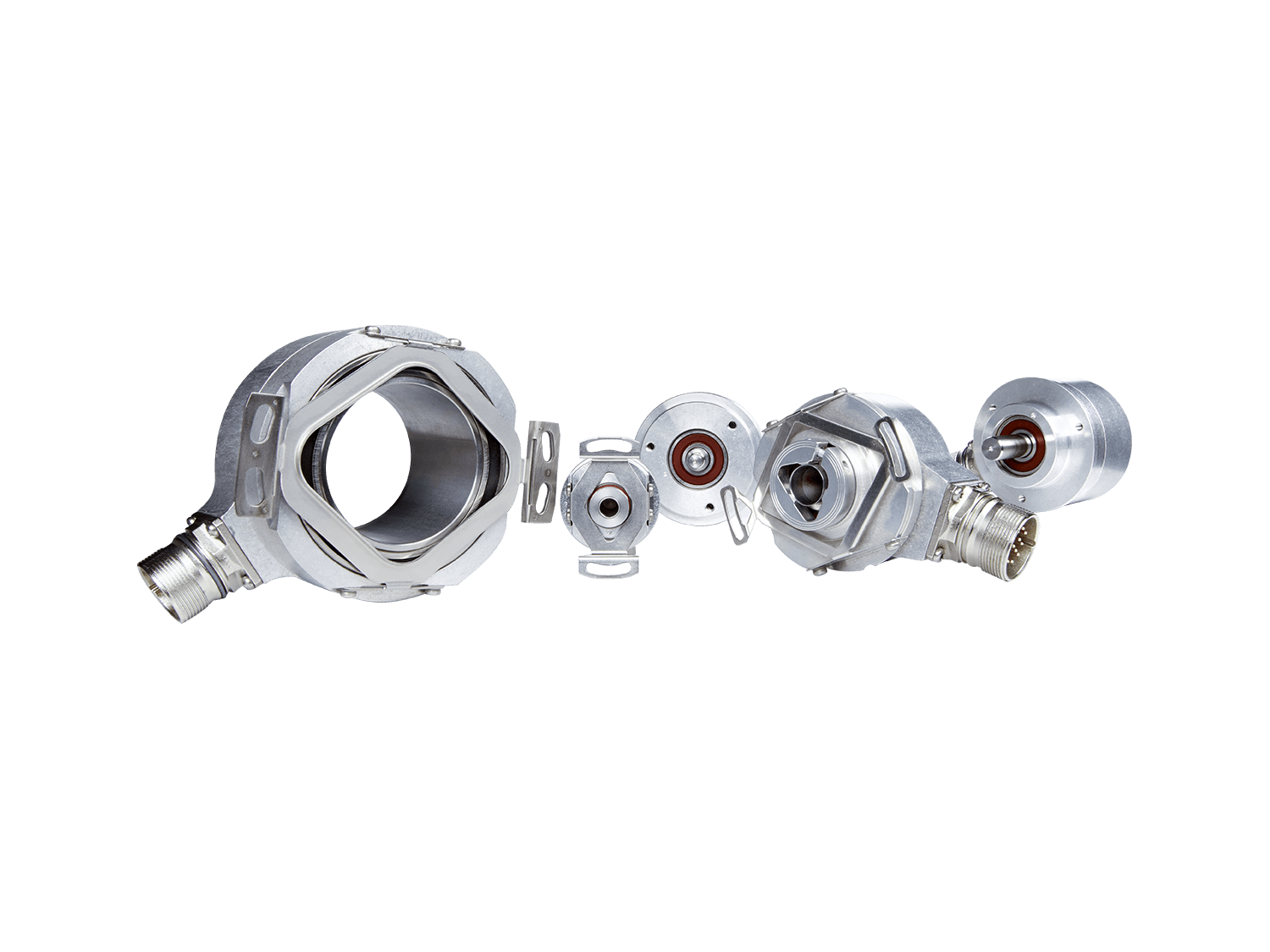

External rotary encoders

Rotary encoders for external installation onto machines and electric motors feature a high protection rating of up to IP66 and permissible operating temperatures of up to 100°C.

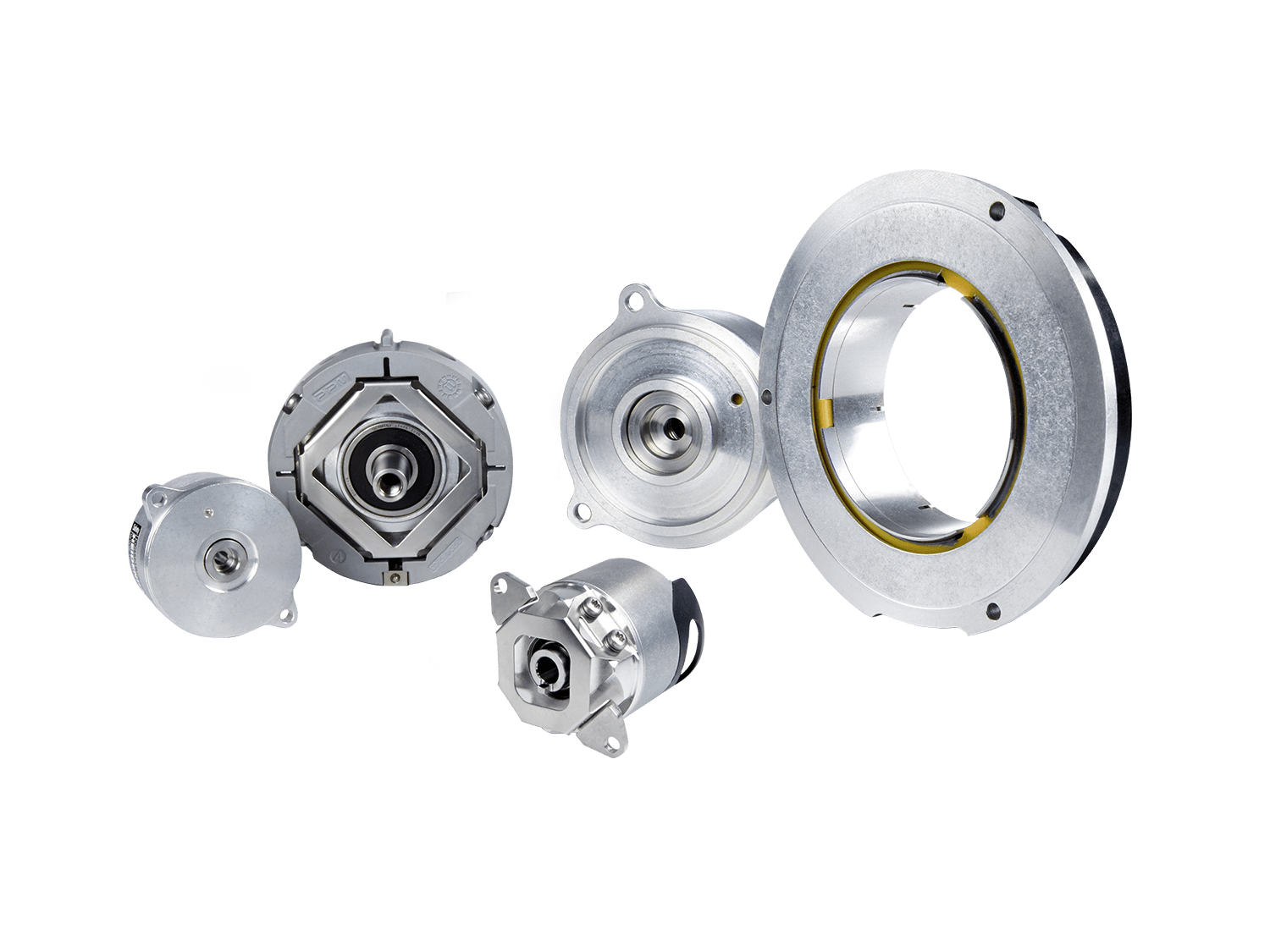

Internal rotary encoders

Rotary encoders for internal installation within devices or motor housings are designed for high vibrations and operating temperatures of up to 120 °C. They offer a protection rating of up to IP40.

HEIDENHAIN connectivity: the right encoders and interfaces for every application

Are you searching for a specific encoder? Use our new encoder selector tool to find the right one for your needs.

Find solutions for your industry

HEIDENHAIN experts are right at home in numerous industries. Let’s discover solutions for your specific applications together. Discuss your requirements with our sales engineers, and let our brands support your market success with their extensive product portfolios and strong industry expertise.

These resources may interest you

Brochure: HEIDENHAIN Rotary Encoders

Learn more about HEIDENHAIN rotary encoders, including specifications and electrical connection information.

Download PDFSafety-Related Position Measuring Systems

HEIDENHAIN offers encoders that can be used in safety-related applications with purely serial data transmission via EnDat 2.2.

Download PDFFrequently asked questions

Product success stories

Applications for medical therapy

Inaccuracies in the positioning or guidance of the therapy instruments can have far-reaching consequences.

Read more

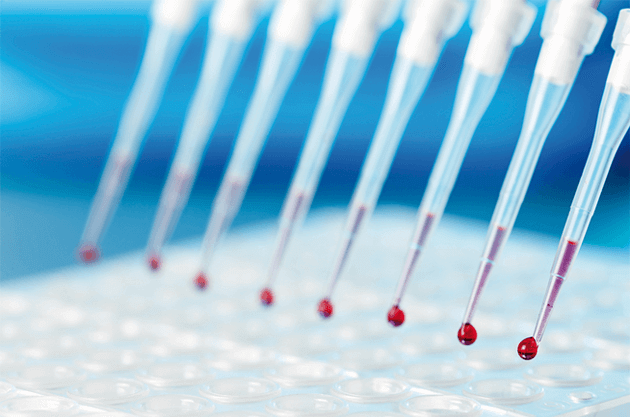

Applications in the laboratory

Modern medical laboratories are characterized by highly automated processes with a high degree of repeatability. Their task is the analysis of very small individual samples in large charges within a very brief time.

Read more

Resolvers vs. encoders for motion control

The phrase “more precise control” would generally drive the solution towards an encoder over a resolver. The application of dry food packaging however might tend to drive it back towards a resolver. Here are some characteristics you can consider to help make the decision.

Read moreRelated news

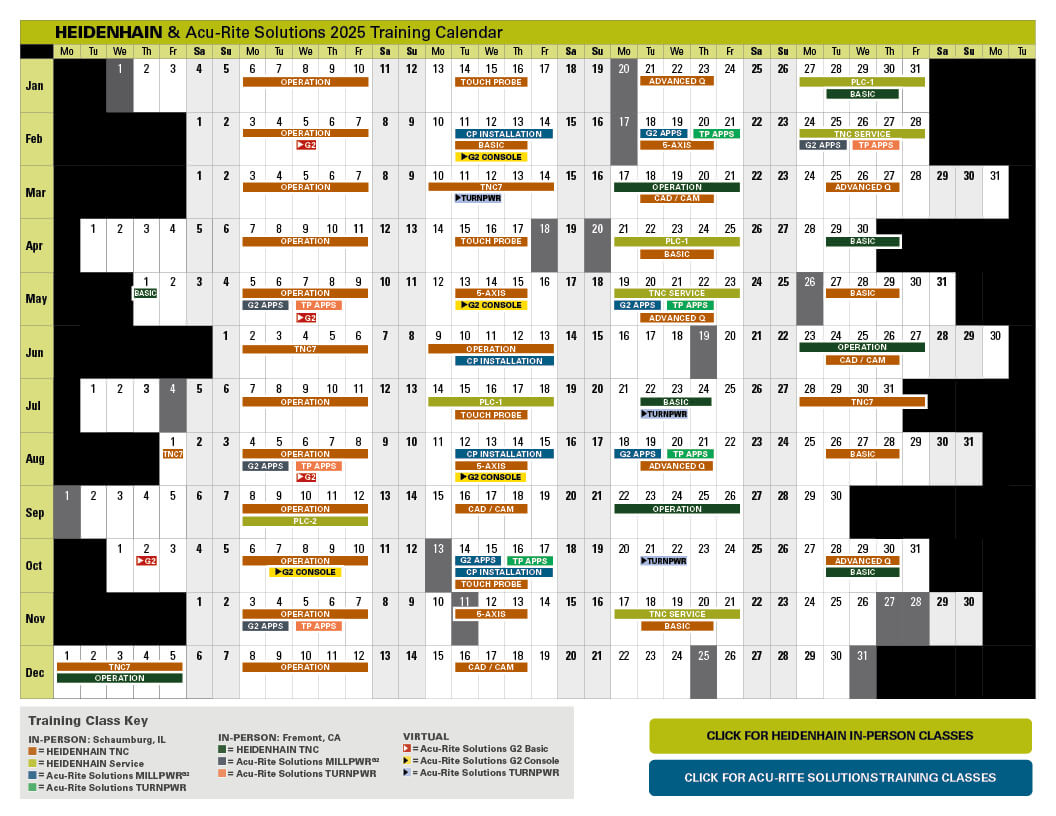

2025 TNC training calendar released

2025 TNC Training Calendar: Click image to open interactive PDF Technical qualification and continuing training are indispensable for achieving ...

HEIDENHAIN innovates: IMTS 2024 highlights

IMTS 2024 was another incredible success for HEIDENHAIN, with excitement and innovation on full display throughout the week. Visitors ...

How the TNC7 helps overcome common CNC control challenges

While machine tools have long been the focal point of standardization efforts, the spotlight is shifting toward CNC controls. ...