TS 760 and TS 750 workpiece touch probes: In-process machining progress monitoring

Leverage in-process workpiece monitoring. For this task, HEIDENHAIN is introducing the new TS 760, an even more accurate variant of the familiar TS 460 workpiece touch probe with cleaning jets and EnDat support. The TS 750 was developed specifically for in-situ workpiece inspection in grinding applications.

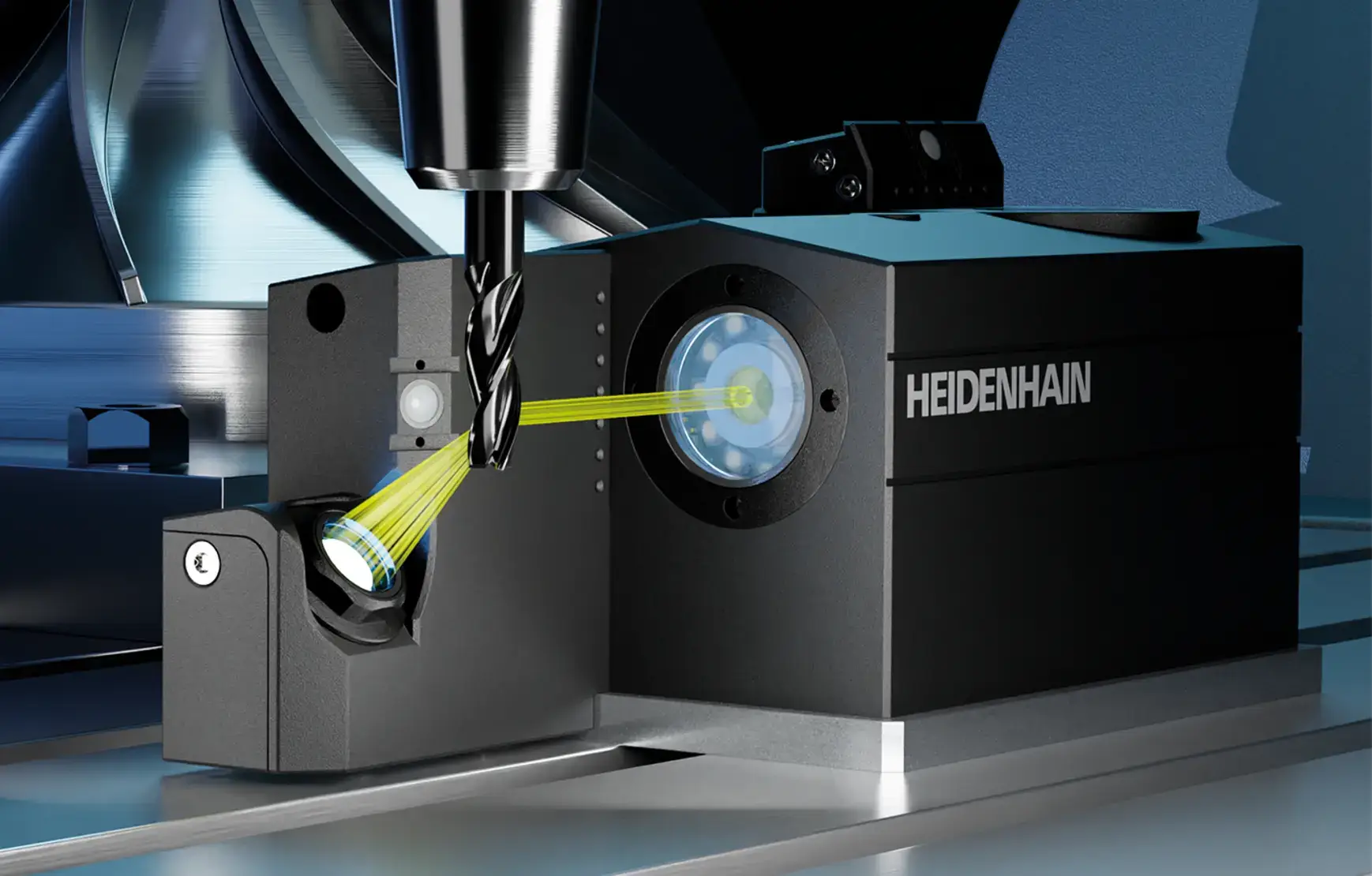

VT 122 vision system: holistic tool inspection inside the machine

The VT 122 measuring camera fulfills three tasks within one system: tool presetting, tool inspection, and tool wear measurement as with a microscope. The VTC software enables automated and time-saving in-process tool inspection and breakage monitoring inside the machine. As a result, you can monitor and document tool condition and wear during unattended shifts, for every tooth and from different perspectives.

TD 110 tool breakage detector: Touchless tool breakage detection

Perform in-process tool breakage detection for any tool starting with a diameter of 0.4 mm and a tooth length of 2 mm, and save up to six seconds for each tool change compared with laser-based systems. The TD 110 inductive tool breakage detector from HEIDENHAIN touchlessly detects rotating tools as they pass by at rapid traverse. The detector can be installed as a retrofit in nearly any machine tool and connects to the control via a touch probe interface. If the control doesn’t receive the expected switching signal, then it can send a message, stop the NC program or perform some other user-defined action. Cost and time savings, along with greater process reliability, are the result.