Canadian mold shop tracks growth

Founded in 1987 in Windsor, Ontario, Canada, ServiceMold + Aerospace Inc. is not your typical mold shop. While the core competence remains the design, engineering and building of molds for the automotive industry, the company has emerged as a contract, build-to-spec supplier of parts for many throughout North America and Europe, including for aerospace and medical customers.

The early years saw steady growth from the production of molds for automotive and consumer goods. Always committed to using the latest technologies for CAD, CAM programming, ServiceMold established a reputation for quality work, problem-solving and on-time delivery, quickly becoming a reliable partner to their customer base.

Then, our industry changed.

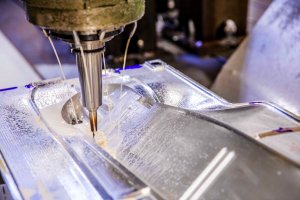

5-axis detailing of steel details for aerospace project. Image courtesy of Zimmermann.

As ServiceMold President Martin Schuurman explains, “In 2006, we purchased our first 5-axis machine, a Zimmermann with a HEIDENHAIN iTNC 530. The path control and contour fidelity of HEIDENHAIN controls is superb and masterfully addresses the conflict between fast, smooth and accurate. The acquisition gave us the ability and capability to explore entering the aerospace market. After a number of calls and quotations, we scored a small order from a major Tier 1.” Sales began to grow, some years by more than 25%, Schuurman says proudly. By 2013, there were four additional Zimmermann machines on the floor and the existing facility had filled nearly to capacity.

The company acquired property adjacent to the current facility in Windsor and erected a new building in 2016, giving the company a capacity of 64,000 square feet. They purchased three Zimmermann FZ33 milling machines, two with 394’’ in the x-axis and the largest one, with 630” x-axis, 138” y-axis and 78” z-axis, giving the shop a substantially greater workpiece capability and opening up more opportunities in the aerospace structure market. In something of a perfect storm scenario, the emergence of composites in the aerospace industry enabled Service Mold to pursue the huge layup mandrel market to a much greater degree.

Always thinking strategically, Schuurman had an early ongoing commitment to pursue and maintain full certification or registration as an ISO, AS9100 rev D, CGP and ITAR facility, all of which are in force today. “We quickly realized what it would take to continue proving our worth in all the various industries and we went after those certs with a great determination.”

Likewise, the company introduced more machining capabilities plus welding and today is exploring the benefits of in-house heat treatment to max up its vertical integration. Such capital investment comes with risk, Schuurman notes, as the dual challenge of finding competent personnel combined with the need to generate sufficient workload to fill the available machining time, which today stands at approximately 15,000 hours annually on the seven Zimmermann machines alone.

5-axis operator on HEIDENHAIN TNC control. Twin FZ37 10-meter machines. Image courtesy of Zimmermann.

As the company currently runs round-the-clock operations, it would appear the investment is paying off.

Never one to rest on his laurels, however, Schuurman explains, “We are a build-to-print company for our customers. By definition, that means we’re always on the hunt for more business and we’ve expanded our component production work substantially, in addition to producing more complex and larger molds and fixtures for our customers.” He also takes great pride in a satellite business he’s developed, over the years. An artistic individual, Martin Schuurman designs custom air vent designs and manufactures the molds to produce them in quantity. What started out as a hobby to decorate his own and family members’ home has blossomed into a thriving business for him. It operates as SMI Ventilation Products, with primarily online sales done through several key distribution customers.

5-axis machining on FZ37 of aerospace steel bond tool. Image courtesy of Zimmermann.

ServiceMold utilizes the Zimmermann and other machining centers to produce molds and components from various alloys of aluminum, steel, Invar and stainless. The twin facilities house boring mills with rotary tables, gundrills, CNC milling machines, 3-axis high-speed mills and, the core of the company’s machining firepower, seven Zimmermann and two Parpas Diamond 5-axis high-speed machining centers, also with HEIDENHAIN TNC controls. At the high end of the Zimmermann lineup are machines with the company’s unique portal milling head, plus an FZ33 Compact, which allows large aluminum and composite structures to be machined without moving them, as the workpiece rests on a fixed table, while the rigid portal travels in the x-direction. The moving bridge on the machine comprises a rigid portal, cross- and z-slides plus the milling head.

Additional Zimmermann machines on the floor at ServiceMold include three FZ37 5-axis portal milling machines and three FZ30 open table 5-axis portal milling machines, ideal for the one-off and short run work done so often at ServiceMold.

Also in-house here are a CMM with 30,000-pound load capacity and ion laser tracker for the large workpiece scanning done on the floor of the facilities here. All data can be captured in a point cloud and instantly analyzed against the CAD files for accuracy and stress points.

Another emerging market for ServiceMold is the orthopedic industry, where the high accuracy of the Zimmermann machines in Aerospace inspired the company to venture into medical device machining. Since medical parts are usually high mix, the ability to easily adjust HEIDENHAIN programs after they are postprocessed from CAM comes in handy. “We’re currently working with an orthopedic surgeon, producing joining plates for humerus and femur sections, something we’d never have considered a few years ago. With the programming speed and high degree of flexibility in our production work now, it’s not only become possible, but also profitable,” he muses.

FZ37 machine with 5-axis TNC operator. Image courtesy of Zimmermann.

Still, the home base, with over 70% of the sales for the company, remains the aerospace market, including a favorite project for Martin Schuurman, one he describes with great excitement. “We have been involved in manufacturing parts for servicing the International Space Station.” As happens with most workpieces in this market, there is an extremely high degree of material removal involved in the production of this workpiece and Schuurman notes the Zimmermann machine rigidity and high-precision moving milling head make the job much easier to accomplish and repeat.

Cornelius Kiesel, president of Zimmermann for North America, with its headquarters located across the river from Windsor in the greater Detroit area (Wixom, Michigan) comments, “We have forged a solid, good faith working relationship with ServiceMold since that first sale in 2006. Today, ServiceMold is one of our largest customers in the world. Zimmermann has other customers like Martin Schuurman and our machines were a perfect fit for his requirements, plus they offered some added advantages such as the latest HEIDENHAIN TNC controls and its Dynamic Efficiency and Dynamic Precision packages that have helped ServiceMold move into other markets and other types of jobs over the years. Remember that HEIDENHAIN Dynamics packages comprise functions that compensate oscillations and chatter that would lead to blemishes on the workpiece finish, that are not only highly undesirable for mold makers. Chatter reduces tool life and increases the wear on machine components like ball screws, guideways and the spindle, which subsequently increase the total cost of ownership.

5-axis detailing of automotive aluminum mold. Image courtesy of Zimmermann.

“When you can partner with a customer and grow together, there are few satisfactions in business that compare. It’s a very solid relationship and we’ve been quite pleased with the results. Martin brings our team new challenges all the time and we respond. The synergy between our companies and their respective talents makes something very special happen and that’s exciting,” Kiesel notes. Schuurman adds, “Our partnership with Zimmermann has brought about many expectations over the years and Cornelius and his team have delivered for us.” He adds “at the same time the support from HEIDENHAIN has been great both on the application and service side. HEIDENHAIN ramped up its support team and now provides the same high-level assistance we are used to in our home market.”

As a further testimony to the value of the Zimmermann machines at ServiceMold, Kiesel notes his customer has recently rebuilt the original machine purchased, retrofitting a new milling head design, among other mechanical and controls upgrades.

Schuurman notes in particular that the linear motor movement and high-speed spindles on the machines are key benefits in the precision machining of aluminum with substantial metal removal rates.

Among the many and varied components produced at this shop, in addition to the myriad molds created each day, are refrigerator trays, washer lids as well as a 22” barrel inlet for aircraft engines, which starts as a 23”diameter aluminum block, usually 15-16” high that has material removed to reduce the piece to less than 5 pounds.

Climate-controlled environment for large 5-axis machines: (2) FZ37 10-meter and (1) FZ37 16-meter. Image courtesy of Zimmermann.

As Schuurman points out, a key to the flexible nature of his company is the fully programmable capabilities of the Zimmermann machines and HEIDENHAIN controls. Especially with the new TNC 640 which has color-coded NC code, the smart.Select option and a comprehensive help menu make programming much easier. The graphics in the simulation mode have been enhanced and can now show the tool path with code numbers and in different colors for different machining steps. A new on-board cutting data calculator lets the operator do the most basic feed rate (per teeth, contour feed rate) calculations right at the machine.

“We’ve worked very hard over the years to carve out some unique niches for our shop and we have a very solid reputation in various industries. That’s given us great pride and, on a practical note, greater stability and protection from the economic volatility in certain vertical markets.”

ServiceMold runs various CAD programs, including Catia and NX CAD, post-processing in-house to run the HEIDENHAIN CNC on each of the Zimmermann machines. HEIDENHAIN’s contour tolerance cycle called Cycle 32 is outputted with every NC code and is easy to adjust afterwards if deemed necessary. It easily allows the user to define the width of the tolerance band, the high-speed cutting mode and an angle tolerance for the rotary axes.

Weekly certification of the machines are done onsite, with volumetric compensation calculation done with the help of KinematicsComp, a HEIDENHAIN control option. Compensation of the rotary axes for thermal and static errors can also be performed before or during jobs with a canned cycle available on the control.

Service Mold is AS9100 Rev. D and ISO 9001:2008 Certified, Controlled Goods Program Registered and ITAR Compliant.