January 15, 2021

Inductive vs. optical vs. magnetic encoders: how to choose

Where magnetic encoders use positive and negative poles and optical encoders use light passing through a disc, inductive encoders are a little more complicated. Inductive encoders have charged coils that are passed over by a passive disc, modulating what charges the sensor receives. There are only a few companies in the world that have the expertise or technology to do it.

It makes sense that when there isn’t a need to spend on a high-end optical encoder, the most common thought is to look directly to magnetic encoders. Sometimes that’s the right move, but when using an inductive encoder is an available option, your search shouldn’t be limited to magnetic-or-optical. Inductive encoders offer a good middle ground, both in terms of what they can do and how much they cost. Let’s compare some of the strengths and weaknesses of optical, inductive and magnetic style encoders and where they’re best applied.

Key considerations for selecting which device is best

Common applications

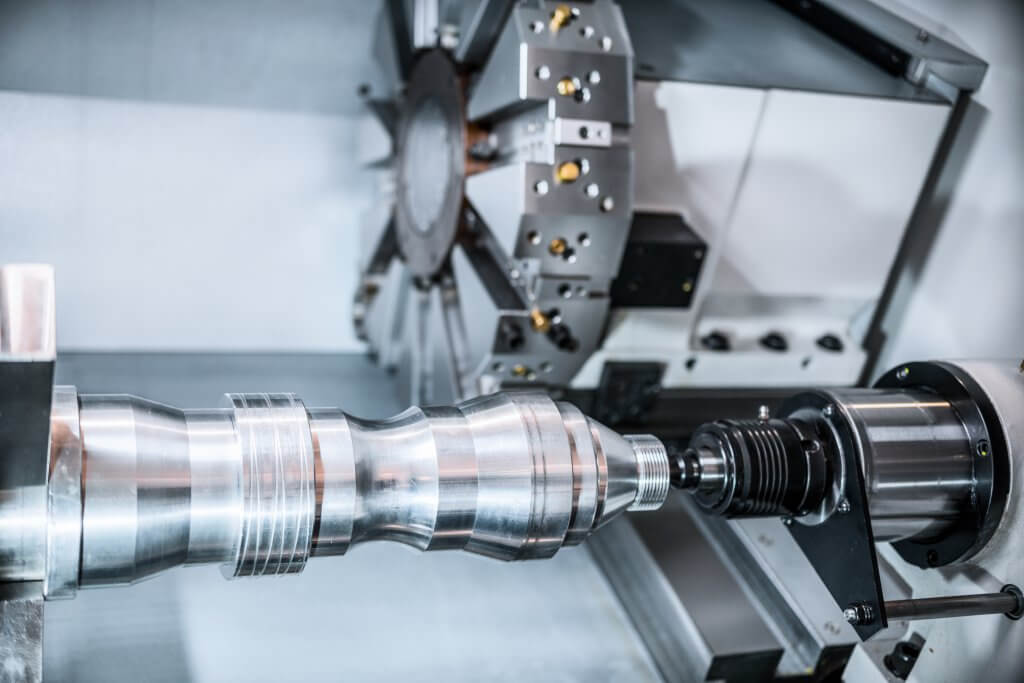

If you’re looking for extreme accuracy or need to facilitate highly dynamic motion, optical encoders with their repeatable accuracy and resolution are the best choice. Examples of these kinds of applications

include pick-and-place robots, telescopes, antennas and machine tool applications like a CNC lathe or mill.

Magnetic encoders are good for commodity-type projects where several of the same encoder are installed. Mining operations are a good example, where vibration goes beyond 30 or 40 Gs and debris is hard to avoid.

Inductive encoders combine the contamination and vibration insensitivity of magnetic with higher accuracy that approaches the level of optical solutions. They fit nicely in general automation systems and work well with different types of servo motors ,medical applications like CT scanners and in the robotics industry.

Environmental factors

Where your encoders will be installed and what will be going on around them will always be something to consider. Because of the type of scanning, optical encoders do their best work in cleaner environments. However, it’s not always an issue because there are a lot of different mounting and sealing options that can be used to keep them clean.

As already mentioned, magnetic encoders are great in situations where vibration, anything over 30-40 Gs, and/or lots of contamination are a risk. One important thing to note about magnetic encoders is that their internal magnets can be interfered with if there’s a magnetic brake near the solution, which would then influence the signal being generated.

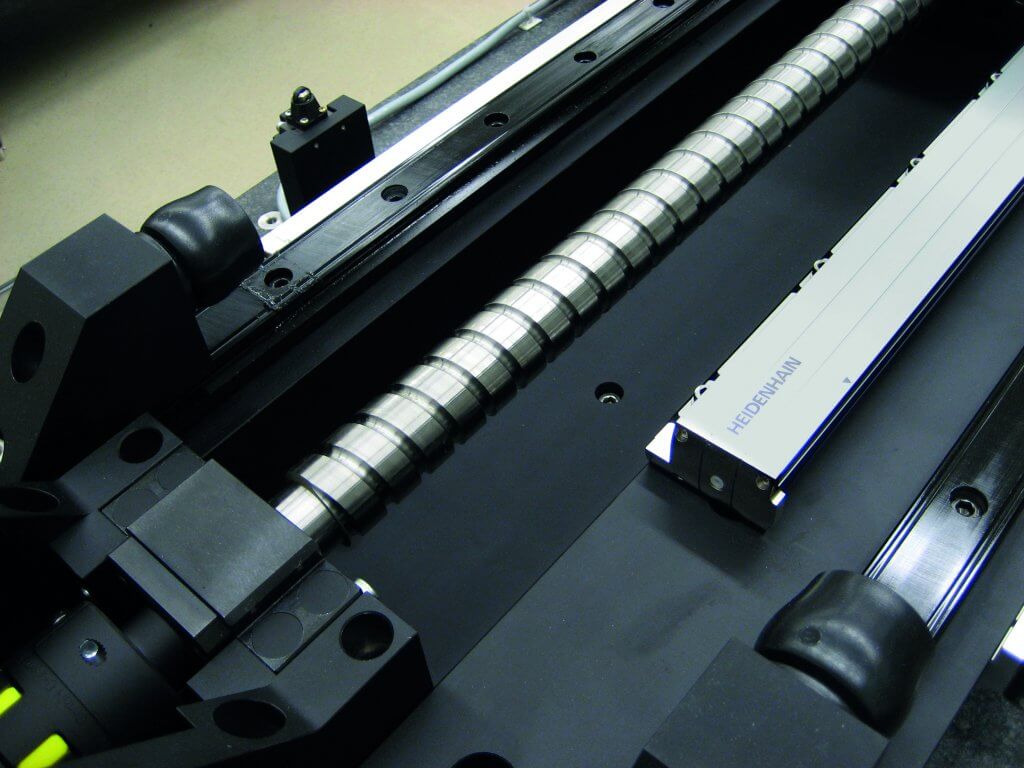

Inductive encoders are not concerned with magnetic fields and can also handle high levels of vibration or contamination while also providing additional accuracy over magnetic solutions. The biggest challenge with inductive encoders is ensuring that the gap between sensor and rotor is held throughout the operation of the application.

The biggest advantages

When you’re looking for the “best solution,” start with optical encoders. Their accuracy, repeatability and resolution capabilities are unmatched. They are the most common solution and have many variations to fit the needs of multiple applications. That said, if you have a higher accuracy requirement, but the application does experience high vibration or contamination, the best solution may be an inductive option.

If a low-cost solution is the goal, magnetic encoders are a good place to start. They’re compact enough to fit in tight spaces and they’re fairly inexpensive.

Inductive encoders are a kind of Goldilocks solution: not the most accurate, but enough for most applications, while also able to withstand various different environments and situations.

Inductive encoders are a kind of Goldilocks solution: not the most accurate, but enough for most applications, while also able to withstand various different environments and situations.

Sure, inductive encoders are a little more difficult to understand, but their above-average accuracy paired with above-average resilience make them the ideal choice—for a number of applications.

In 2015 HEIDENHAIN acquired AMO, arguably combining the two most successful makers of inductive encoders. Click here to learn more about AMO and AMOSIN® measuring principle that guides the development of their linear and angle encoders.